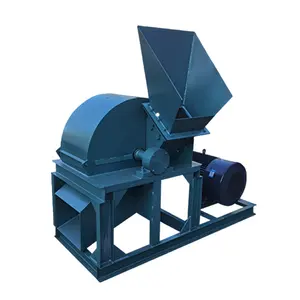

Introduction to Wood Chippers for Paper Mills

Wood chippers designed for paper mills are specialized machines that process wood into chips for various applications. These robust and efficient devices are crucial for converting large wood pieces into smaller, uniform chips, which are essential for the papermaking process. The versatility of these chippers allows them to handle a range of wood types, including branches and whole trees, making them a valuable asset for paper mill operations.

Types and Applications

There are several types of wood chippers tailored to meet the needs of paper mills. From high-capacity chippers for industrial use to more compact models for smaller operations, each type serves the purpose of waste management and raw material preparation. The chips produced are not only used in papermaking but also serve as raw material for biomass fuel, particleboard, and wood pellets, showcasing the machine's multifaceted applications.

Features and Materials

The construction of a wood chipper for paper mill involves durable metals, ensuring longevity and resistance to harsh operational conditions. These machines typically feature sharp cutting blades, powerful motors, and mechanisms to facilitate consistent chip size. The design prioritizes user safety and efficiency, with some models offering features like auto-feed systems and reversible blades for enhanced performance.

Advantages of Using Wood Chippers in Paper Mills

Utilizing a wood chipper in a paper mill setting offers numerous advantages. It significantly reduces the size of wood waste, making disposal or repurposing more manageable. The ability to process wet and dry wood adds to the machine's flexibility, while the production of uniform chips is critical for the quality of paper products. Moreover, the reduction of wood waste volume can lead to cost savings in transport and storage.

Choosing the Right Wood Chipper

Selecting the appropriate wood chipper for paper mill use is vital for operational efficiency. Factors to consider include the size and type of wood to be chipped, the desired chip size, and the machine's power source, which can be an electric motor or a gasoline engine. The choice depends on the specific needs of the paper mill, such as the volume of wood to be processed and the availability of power sources.

Maintenance and Durability

Maintenance is a key aspect of ensuring the longevity of a wood chipper for paper mill. These machines come with manuals that outline maintenance schedules and procedures to keep them running smoothly. The sturdy construction of the chippers is designed to withstand the demands of continuous operation, emphasizing the importance of regular upkeep to maintain performance and durability.

Incorporating a wood chipper into a paper mill's equipment lineup can greatly enhance the management of wood waste. By choosing the right model and adhering to maintenance guidelines, paper mills can improve their operational efficiency and contribute to a more sustainable production process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4