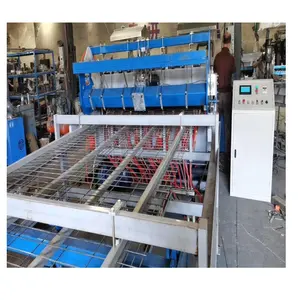

Alibaba.com showcases a diverse range of wire mesh welding machines designed to meet various production needs. Among the offerings, you'll find fully automatic machines capable of handling wire diameters from 3 to 6mm, providing spot welding solutions for steel wire roll mesh fabrication. These machines come equipped with features like coil wire feeding systems, which streamline the manufacturing process for metal fences and similar products.

The platform also lists specialized machines for creating 3D panel fences and machines tailored for constructing reinforced mesh, suitable for building applications. For more intricate tasks, there are options like the multi-head spot welding machine, which is adept at producing steel grating and other complex structures.

For those requiring high-speed production, certain models on Alibaba.com offer rapid welding capabilities, achieving up to 130 welds per minute. These are ideal for both panel and roll mesh production. Additionally, machines designed for specific applications, such as chicken cage manufacturing or security fence panel welding, are also available, demonstrating the versatility of the wire mesh welding equipment on the platform.

In terms of automation, the selection includes fully automatic lines that integrate seamlessly into existing production setups, enhancing efficiency and output. These machines are adept at working with galvanized wire, reinforcing the durability of the end product. With varying aperture sizes and the ability to handle different materials, these machines are engineered to cater to a broad spectrum of industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4