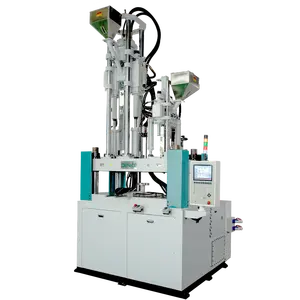

Introduction to Vertical Injection Moulding Machines

Vertical injection moulding machines are specialized equipment used in the manufacturing industry to create a wide array of plastic products by injecting molten material into a mold. Unlike their horizontal injection molding machine counterparts, these machines utilize a vertical orientation for the injection process, offering unique advantages in terms of footprint and the ability to insert components into the mold.

Types and Applications

The versatility of vertical injection machine types ranges from simple, single-action models to more complex systems, such as the vertical injection molding machine with rotary table. This diversity allows for their application in various sectors, including automotive, consumer electronics, and medical device manufacturing. The rotary table design, in particular, facilitates the integration of automation and can enhance productivity by allowing simultaneous prepping and injection processes.

Features and Materials

Vertical plastic injection machines are designed to handle a broad spectrum of materials, including thermoplastic, thermoset, and silicone. Key features often include precision temperature and pressure controls, which are critical for producing consistent, high-quality molded parts. The construction of these machines typically involves robust materials that contribute to their longevity and reliability in production settings.

Advantages of Vertical Moulding

The advantages of vertical moulding are numerous. These machines are particularly beneficial for producing parts that require inserts or overmolding, as their vertical orientation allows for easier placement and removal of parts. Additionally, vertical plastic molding machines often require less floor space, making them ideal for facilities with limited area.

Efficiency and Performance

Efficiency in cap production and other plastic parts is a hallmark of vertical plastic injection moulding machines. Their design often leads to reduced cycle times and energy consumption, which in turn can increase the capacity and profitability of a manufacturing facility. Performance-wise, these machines are engineered to meet rigorous production demands with consistent output quality.

Choosing the Right Machine

Selecting the right vertical injection moulding machine involves considering several factors, such as clamping force, injection size, and machine features. Prospective buyers can find a variety of options on Alibaba.com, including used vertical injection moulding machines for more cost-effective solutions. It's important to analyze the specific needs of your manufacturing project to ensure the machine you select aligns with your production goals and quality standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4