Understanding Used Vibrating Screens

The industrial landscape is replete with separation challenges, from food grain processing to mineral extraction. A used vibrating screen is a pivotal piece of equipment in this context, facilitating the segregation of materials by size through vibratory motion.

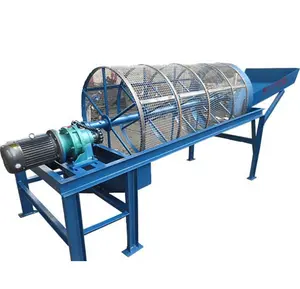

Types of Vibrating Screens

Vibrating screens come in various forms, each suited to specific tasks. The high-frequency vibrating screen is adept at transforming larger particles into fine dust, effectively sifting valuable materials from waste. In contrast, the dewatering screen is tailored for the mining industry, capable of managing the heavy-duty separation of sludges and rocks in moist conditions. For more precise mineral separation, circular vibrating screens are advantageous, while linear vibrating screens are optimal for grain processing, featuring a rectangular design and sieves that facilitate starch extraction.

Applications of Vibrating Screens

The utility of a used vibrating screen spans various industries. In mining, it plays a critical role in gold extraction and other mineral processing. The food industry also benefits from specialized screens like the ultrasonic vibrating screen, which is essential in separating fine ingredients during food production, such as in brewing or egg processing. These screens are versatile enough to be used in smaller settings, including restaurants or even home use.

Features and Advantages

A used vibrating screen offers several features that make it an asset in industrial processing. Its ability to separate materials based on size through vibratory motion is invaluable. The screens are designed for durability and efficiency, with various models available to handle different materials and separation requirements. The advantage of sourcing a used screen is the potential for cost savings without compromising on functionality.

Materials and Construction

The construction of a used vibrating screen typically involves robust materials capable of withstanding the rigors of industrial use. Stainless steel is a common choice for its resistance to corrosion and ease of cleaning, essential for both mining and food processing applications. The design and engineering of these screens ensure longevity and consistent performance in various industrial settings.

Choosing the Right Vibrating Screen

Selecting the appropriate used vibrating screen requires consideration of the material to be processed, the environment of operation, and the desired level of separation efficiency. Alibaba.com offers a diverse array of options to meet these needs, connecting buyers with a global network of suppliers. The platform facilitates the discovery of the ideal used screen for any industrial separation task, without the constraints of brand affiliation or promotional bias.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4