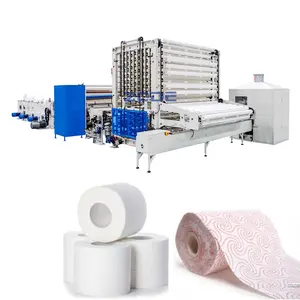

A toilet paper machine makes thin, lightweight toilet paper that's absorbent and sturdy. It can be fully automated or semi-automatic and produce toilet papers that will be well-liked by customers. The tissue paper-making machine draws in large jumbo rolls and cuts them into standard-sized rolls. Then, it wraps the tissue paper in plastic for easy storage and transport.

The operating mechanism of a toilet paper machine

Paper pulp, such as recycled paper or wood pulp, is the primary input into the process. The toilet paper maker equipment thinly layers a suspension of wood fibers in water, spreads it evenly, and drains the water. Creating sheets involves dripping water from them in the forming area, then forcing it out between rolls in the press area. Finally, the leftover water must be heated and dried using thermal energy. The Yankee dryer surfaces are typically hot, and the hot air from the Yankee hood impinges on the sheet to dry it. The doctor blade's geometry, the adhesive's tensile strength, the speed differential between the Yankee and final sections of the tissue paper machine, and the properties of the paper pulp all affect how the paper crinkles or crepes.

Fully-automatic toilet paper machine

The fully-automatic toilet paper-making machine uses computer programming to do coreless automated paper rolling, glue spraying, trimming, and glue sealing. Rewinding toilet paper rolls is usually used to reduce the diameter of large jumbo rolls. It can soften the paper and provide a consistent double-sided look on the final product. A toilet paper converting machine that produces identical-sized rolls will also save resources. A single step prevents paper loss by automating the entire production line.

Considerations when choosing a toilet paper machine

Bathroom tissue-making machines come in all shapes, sizes, dimensions, blade types, and more. For instance, the jumbo roll toilet paper-making machine adds an embossing device to the standard toilet paper roll machine. The idea is to rewind multilayer base paper while creating a gorgeous, non-separated-looking roll. A good understanding of the installation process of a tissue paper manufacturing machine will help owners recognize that they may need an installer and operator.

![[JT-120B] China high speed automatic toilet tissue paper core machine paper tube making machine](https://s.alicdn.com/@sc04/kf/HTB1OIKDyxSYBuNjSsphq6zGvVXad.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4