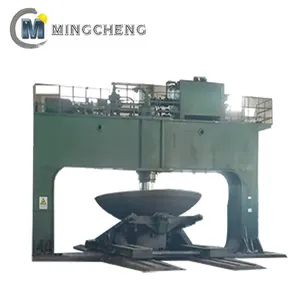

Introduction to Tank Dish End Flanging Machines

Tank dish end flanging machines are specialized pieces of equipment designed for the precise shaping of tank ends. These machines are essential in various industries, including petrochemical, pharmaceutical, and food processing sectors, where tank fabrication is a critical process. The role of these machines is to produce tank ends with specific flanges, ensuring a perfect fit for further assembly.

Types of Tank Dish End Flanging Machines

The category encompasses several types of machines, such as hydraulic and pneumatic tank dish end flanging machines. Each type serves a unique purpose and is selected based on the specific requirements of the tank end shaping process. The hydraulic variant is known for its robust performance in heavy-duty operations, while pneumatic models offer precision in more delicate tasks.

Components and Functionality

Tank dish end flanging machines consist of critical components such as clamp dies, bend dies, pressure dies, and wiper dies. The bend die is integral to the machine, determining the internal radius of the flange. The clamp die secures the tube to the bend die, preventing slippage during the process. The pressure die assists in guiding the tube along the curve of the bend die, while the wiper die smoothens the surface, eliminating wrinkles that may occur during bending. Additionally, a mandrel is often used to maintain the integrity of the tube, preventing it from collapsing under pressure.

Applications and Features

The application of tank dish end flanging machines extends to creating precise flanges on tank ends used in storage and reactors. These machines feature advanced controls for accuracy, consistency, and repeatability in production. The adaptability of these machines allows for processing a wide range of materials, including stainless steel, carbon steel, and other alloys, catering to the diverse needs of tank manufacturing.

Advantages of Modern Flanging Technology

Modern tank dish end flanging machines offer numerous advantages, such as enhanced precision and increased production speed. The use of these machines leads to a reduction in material wastage and ensures a high level of consistency in the final product. The automation capabilities of contemporary flanging machines also reduce the need for manual intervention, thereby minimizing the risk of human error.

Choosing the Right Machine on Alibaba.com

For businesses seeking to procure a tank dish end flanging machine, Alibaba.com presents a comprehensive collection from various suppliers. The platform facilitates the selection process, allowing buyers to compare different models and features to find a machine that aligns with their operational requirements and material specifications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4