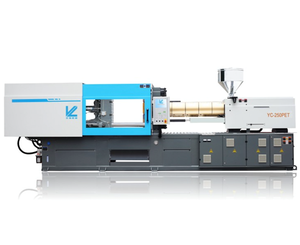

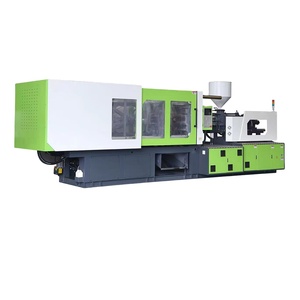

Introduction to Small Injection Moulding Machines

Small injection moulding machines are pivotal in the manufacturing sector, offering precision and efficiency in producing a wide array of plastic components. These compact units are engineered to meet the demands of various industries, from consumer electronics to packaging. They are particularly noted for their ability to handle small to medium-sized production runs with consistent quality.

Design and Applications

The design of a small injection moulding machine is focused on versatility and durability. These machines are utilized across multiple sectors, including but not limited to, pharmaceuticals, food and beverage, and the automotive industry. Their robust construction ensures a prolonged service life even under the rigorous conditions of high-speed operation. The adaptability of these machines allows them to produce everything from PVC pipe fittings to intricate electronic parts.

Technical Features

Each small injection moulding machine incorporates a special screw design that enhances plasticizing capabilities, ensuring efficient shot weights and speeds. The clamping force of these machines varies, capable of resisting significant external machining forces, which is crucial for maintaining dimensional accuracy in finished products. The single-cylinder system with a servo-valve is a testament to the machine's responsive operation.

Material Handling and Precision

The small injection moulding machine is adept at processing various plastic granules, transforming them into precise preforms. This precision is further enhanced by the steel bush in the clamping unit, which is designed to minimize wear resistance and lubrication effects, thereby reducing operational costs. Such features underscore the machine's capability to produce components with improved accuracy, essential for high-end applications.

Advantages of Small Injection Moulding Machines

Investing in a small injection moulding machine from Alibaba's wholesalers means accessing equipment that's tailored to your specific production needs. The machines' special design ensures that you utilize the exact clamping force necessary for your tasks, without excess energy consumption. Additionally, the reduced wear and tear on components like the steel bush lead to lower maintenance requirements and operational costs.

Choosing the Right Machine

Selecting the right small injection moulding machine involves considering the machine's capacity to handle the intended product size and complexity. Alibaba's platform offers a diverse range of machines to suit different industry requirements, ensuring that businesses can find the right match for their plastic processing needs without the concern of excessive defective rates.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4