A rice miller is an invaluable tool in agriculture and food processing that plays a crucial role in transforming raw rice grains into the quality essentials that fill our plates. For farmers, millers, and consumers alike, the importance of this equipment lies in its ability to efficiently process rice, offering a streamlined solution that ensures the removal of husk, bran, and other impurities. From enhancing the economic viability of rice production to delivering high-quality rice for consumption, a rice milling machine is an essential asset in the journey from the paddy field to the dinner table.

What is a Rice Miller?

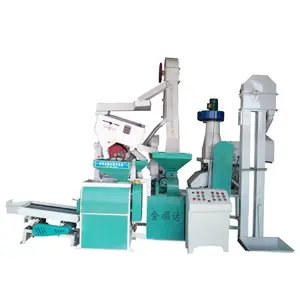

A rice miller, also known as a rice mill, is a machine designed specifically for processing rice. The primary function of the rice miller is to remove the husk, bran, and other unwanted materials from raw rice grains, leaving clean, polished rice ready for cooking or further processing. Milling rice has a long history dating back thousands of years. Archaeological evidence suggests that early milling methods were developed in ancient civilizations such as China and India. The process has evolved significantly, with traditional hand pounding and milling techniques giving way to more sophisticated methods driven by water or steam power. In the modern era, electrically powered rice mills have become prevalent, streamlining the process and increasing efficiency. The longevity of rice milling attests to its crucial role in food production and its continuous adaptation to technological advancements throughout the ages. Modern rice millers often incorporate advanced technologies to automate and streamline the milling process, improving efficiency and ensuring a consistent, high-quality end product. These machines come in various sizes and capacities, catering to the diverse needs of rice producers, millers, and processors.

Where are Rice Millers Used?

Rice mills have applications in various rice production and processing stages. The rice miller's uses and functions can commonly be utilized in paddy fields, where freshly harvested rice undergoes the initial milling process to separate the husk from the grain. Once the milled rice is processed, the equipment plays a vital role in rice processing units, ensuring the grains are polished and cleaned before reaching consumers. Additionally, rice millers are essential in rice mills, processing facilities, and even large-scale agricultural operations where the volume of rice production demands efficient and automated milling solutions.

Types of Rice Millers

The types of rice millers available cater to different scales of operation, processing requirements, and technological preferences. One common type is the traditional hand-operated or small rice miller, suitable for small-scale farmers or households. These manual rice millers are simple and cost-effective, making them accessible to those with limited resources. On a larger scale, electric or diesel-powered rice millers offer increased processing capacity and automation, allowing for faster and more efficient milling processes. Some modern and portable rice millers may also incorporate additional features such as advanced sorting and grading systems to ensure the quality and uniformity of the final rice product. Fully automated rice milling plants integrate processing equipment for commercial and industrial applications, including cleaners, huskers, polishers, and sorters. These integrated systems can handle large volumes of rice, ensuring continuous and efficient milling operations. Some rice millers are designed for specific types of rice, such as basmati or jasmine rice, where the milling process is adapted to preserve the unique characteristics of each rice variety.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4