Alibaba.com showcases a diverse range of reverse osmosis systems designed to meet the varied needs of businesses seeking pure water solutions. Among the offerings, commercial reverse osmosis systems are prominent, tailored for a spectrum of applications from drinking water equipment to large-scale water treatment needs. These systems come in various capacities, including options like the 1000LPH model suitable for distilled pure water purification and the more extensive 200000L per day units that cater to agricultural irrigation and brackish water desalination.

The platform features systems that integrate advanced features such as UV purifiers and water softeners, enhancing the purification process and ensuring the delivery of safe and clean water. For businesses requiring high-volume water treatment, there are industrial-scale options like the 10000LPH reverse osmosis water purifying machines. These are engineered to handle significant water throughput while maintaining efficiency and reliability.

Smaller scale operations are not left out, with systems like the 800 GPD models that are ideal for businesses with less intensive water purification needs. Additionally, smart commercial alkaline water treatment appliances are available, which combine the benefits of reverse osmosis with alkaline water production, offering a dual solution for water quality enhancement.

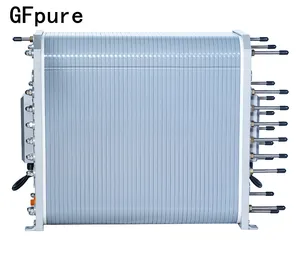

For specialized applications, there are systems like the EDI water filters and ultra-pure water machines, which are capable of producing high purity water for critical processes. The variety extends to compact units designed for tap and underground water purification, ensuring that businesses of all sizes can find a reverse osmosis solution that fits their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4