Introduction to Resin Machines

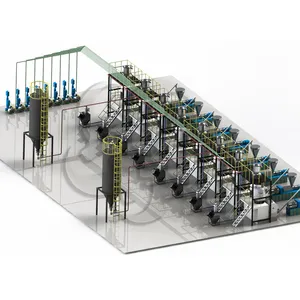

Resin machines are pivotal in the realm of production, offering versatility and efficiency in handling various materials. These machines are engineered to manage and dispense liquids with precision, catering to a broad spectrum of industrial applications. From packaging to product development, resin machines play a crucial role in streamlining operations and enhancing productivity.

Types and Applications

The diversity of resin machines is evident in their ability to accommodate different types of liquids, from viscous substances like glues and resins to more fluid materials such as paints. Their application extends across industries, including but not limited to, pharmaceuticals, food and beverage, and construction materials. Specialized models are designed to handle food-grade liquids, ensuring safety and compliance with industry standards.

Operational Features

Ease of operation is a fundamental feature of resin machines, with designs focused on minimizing labor and simplifying training requirements. Automation is at the heart of these systems, allowing for programming and operation with minimal human intervention. This automation not only bolsters efficiency but also contributes to consistency in production quality.

Efficiency and Cost-Effectiveness

Incorporating a resin machine into a production line can lead to significant time and cost savings. The automatic nature of these machines allows for continuous operation, reducing the need for manual labor and the potential for human error. By optimizing power consumption, these machines offer a balance between operational speed and energy efficiency, which is crucial for maintaining low operational costs.

Material Handling and Advantages

Beyond liquid dispensing, certain resin machine models are adept at processing powders and granules, which is essential for packaging powdered foods and pharmaceuticals. The versatility in handling different materials provides a clear advantage in production flexibility and capability. This adaptability ensures that businesses can meet diverse manufacturing requirements with a single piece of equipment.

Choosing the Right Resin Machine

Selecting the appropriate resin machine involves considering workspace constraints, desired wattage for optimal performance, and the specific type of material to be dispensed. Alibaba.com hosts a variety of suppliers offering machines that cater to these precise needs, ensuring that businesses can find a suitable solution without compromising on efficiency or production quality.

Resin machine technology continues to evolve, integrating advanced features that cater to an expanding range of industrial applications. The right machine can significantly enhance production efficiency, offering a swift return on investment. When sourcing a

resin machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4