Introduction to Power Cord Winding Machines

The power cord winding machine is an essential apparatus designed to enhance efficiency and precision in the production of electrical coils. Utilized extensively in workshops and manufacturing settings, these machines serve a pivotal role in the fabrication of motor repairs, electrical appliance components, and various types of solenoids. The technology behind these machines has evolved to accommodate a range of operational modes, from fully automated systems to manual alternatives, catering to diverse industrial and commercial requirements.

Types and Applications

There exists a spectrum of winding machines tailored to different industrial needs. From autonomous, high-precision models suited for large-scale production to semi-automatic and manual variants ideal for smaller enterprises or specialized tasks, the versatility of these machines is evident. Their applications are widespread, not limited to but including the manufacturing of electrical fans, transformers, and other appliances requiring coiled components.

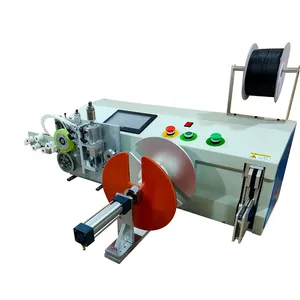

Features and Functionality

A coil winding machine is engineered with features that promote ease of use and consistent output. Many models boast user-friendly interfaces, allowing for quick setup and operation by a single individual. The precision of an automatic winding machine ensures that each coil is crafted to meet exact specifications, which is crucial for maintaining the integrity of electrical components. The adaptability of these machines means they can handle various wire gauges and coil sizes, making them a versatile addition to any production line.

Materials and Construction

Durability is a cornerstone of winding equipment, with construction materials carefully chosen to withstand the demands of continuous operation. The robust design of these machines contributes to a prolonged service life with minimal maintenance requirements, ensuring they remain a reliable component of the production process.

Advantages of Utilizing Winding Machines

Incorporating a power cord winding machine into your operations can significantly reduce labor intensity and enhance production efficiency. The automation of coil winding not only accelerates the manufacturing process but also minimizes the potential for human error, resulting in a more consistent and reliable product. Furthermore, the precision of automated winding can lead to a reduction in material waste, contributing to cost savings and environmental sustainability.

Selection and Procurement

Alibaba.com hosts a comprehensive collection of winding machines, ensuring that you can find a model that aligns with your specific production needs. With a focus on meeting international production standards, each machine is a testament to the commitment to quality. Prospective buyers can explore a variety of options, ensuring the right fit for their operational demands. While Alibaba.com facilitates the connection between buyers and suppliers, it is recommended to engage with suppliers directly to discuss specific requirements and potential demonstrations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4