What is Efficient Poultry Feed Mixer Machine

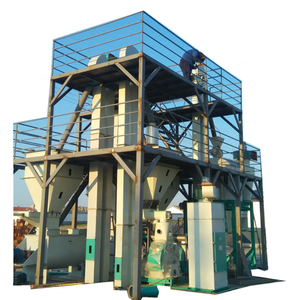

Poultry feed mixer machines are essential equipment in the agricultural industry, specifically designed for blending feed ingredients to ensure that all elements are evenly distributed, and the nutrients are uniformly available to the poultry. These machines are utilized by a wide range of professionals, including farmers, feed manufacturers, and animal product suppliers who require precise formulations for different classes of poultry.

The principle behind a poultry feed mixer machine is simple: it combines various ingredients in the correct proportions to create a well-balanced feed that meets the nutritional requirements of poultry at different stages of growth and for various purposes. These mixers typically feature a rotating drum or paddles that blend the ingredients thoroughly. The design of the machine aims to achieve a high mixing efficiency, ensuring that every particle is fully integrated into the mixture.

Efficiency in a poultry feed mixer machine is determined by several factors, such as the type of mixer, its capacity, the speed of mixing, and the characteristics of the ingredients being blended. With advancements in technology, modern mixers often come equipped with features like programmable mixing cycles, variable speeds, and even computerized systems that can provide more control over the blending process.

Types of Efficient Poultry Feed Mixer Machine

The market offers a variety of efficient poultry feed mixer machines tailored for different scales of production and specific requirements such as speed, uniformity, and capacity.

-

Horizontal Feed Mixer: This type is characterized by its horizontal shaft with paddles that rotate in a trough-like structure. It's particularly suitable for mixing dry ingredients and can handle a higher volume of feed. The design is often used for large-scale commercial feed production.

-

Vertical Feed Mixer: Vertical mixers have a cone-shaped structure with a screw that turns and moves the feed vertically. They are less commonly used but can be efficient for small-scale mixing or specialized applications where space is limited.

-

Ribbon Mixer: A ribbon mixer features a set of blades that move material in two directions at once, resulting in a thorough mix. Ribbon mixers are versatile and can be used for a variety of feed formulations including mash, pellets, and crumbles.

-

Paddle Mixer: Paddle mixers offer a combination of speed and uniformity in feed processing. They are known for their gentle mixing action, which is suitable for premixes and specialized feeds that require minimal handling.

Each type of mixer has its common use cases depending on the specific requirements of the feed manufacturing process—whether it's producing a simple mash or a specialized feed with added vitamins and minerals.

How to choose Efficient Poultry Feed Mixer Machine

Selecting the right poultry feed mixer machine requires careful consideration of several factors related to your specific business needs. Here's what you should keep in mind:

-

Scale of Operation: The size of your operation will largely determine the type of mixer you need. For smaller farms or those just starting out, a simple hand-operated or motorized vertical feed mixer might suffice. Larger operations with more complex needs should consider horizontal mixers or paddle mixers.

-

Available Space: Consider how much physical space you can dedicate to a feed mixer. Vertical mixers are generally more compact and can be a good option if space is limited.

-

Type of Feed: The type of feed you produce will influence your choice. For example, fragile ingredients may require a ribbon mixer to prevent degradation, while more viscous materials might need a plow mixer for thorough blending.

-

Mixing Quality: The quality of the mix is crucial as it directly impacts animal health and productivity. Ensure that the machine you choose can maintain the necessary standard of quality for your specific goals.

-

Power Source: The availability of electricity or other power sources will determine whether you can use an electrically operated or solar-powered mixer.

-

Automation Level: Consider how much automation you need in your feeding process. Fully automated systems can handle more tasks with less labor but may require greater initial investment.

By evaluating these considerations against your operational needs and budget constraints, you can make an informed decision that ensures efficiency in your feed mixing process while maintaining quality standards.

About Efficient Poultry Feed Mixer Machine on Alibaba.com

Alibaba.com is globally recognized as a leading marketplace that connects businesses with a vast selection of Poultry Feed Mixer Machines suited for every need. Whether you're a small-scale farm looking to mix feed efficiently or a large commercial feed plant in need of industrial-grade equipment, Alibaba.com provides access to an array of options from suppliers around the world.

The platform's user-friendly interface allows you to filter through products based on specific features such as key selling points—high productivity or multifunctionality—core components like gearboxes or PLC systems, as well as after-sales service options. This ensures that you find a machine that aligns with your operational requirements while also accounting for serviceability and support post-purchase.

Moreover, Alibaba.com stands out with its Trade Assurance service which helps safeguard transactions and build trust between buyers and suppliers. This commitment to secure and satisfactory trade experiences reinforces why many choose Alibaba.com as their go-to source when procuring wholesale poultry feed mixer machines. With its extensive network covering over 190 countries and areas, Alibaba.com empowers businesses with the right tools to thrive in the competitive world of animal feed production.

Common FAQs for Efficient Poultry Feed Mixer Machine

What is the optimal feed particle size for my livestock?

The optimal feed particle size depends on the type of livestock you are feeding. Larger animals like cattle and horses can handle bigger particles, while poultry and small ruminants typically require smaller sizes.

How does the feed mixer affect the quality of my animal feed?

The quality of the feed mixer's performance directly impacts the health and productivity of the livestock. It is crucial to ensure that the machine can blend the feeds into a homogeneous mixture that is easy for animals to consume.

Can I mix different types of feed in one machine?

Some feed mixers are designed for specific types of feed, while others can handle a variety of ingredients. It's important to check the specifications of the mixer to see if it meets your business needs.

What should I consider when choosing a mixer for a small-scale operation?

For small-scale operations, consider a mixer that balances volume capacity with the size of your operation, offers easy operation and cleaning, and can handle a wide range of feed ingredients effectively.

Are there eco-friendly options available for poultry feed mixers?

Yes, some suppliers offer feed mixers designed with energy-efficient features and made from sustainable materials. It's important to check the product descriptions for these attributes.

How do I know if a feed mixer is easy to operate?

Look for features such as programmable settings, digital controls, and user-friendly interfaces that make operation straightforward and efficient. These can be especially beneficial in large-scale or fast-paced environments.

What safety features should I look for in a poultry feed mixer?

Key safety features include secure guards over moving parts to prevent accidents during operation and emergency stop buttons that halt the machine if a problem occurs. Some models also have alarms for issues like jamming or overloading.

Can I find a mixer that also works as a pellet making machine?

Yes, some feed mixers come with additional features that allow them to produce pellets or serve as extruders. These multifunctional machines can be a valuable addition to businesses looking to streamline their feed production processes.

What after-sales services should I consider when purchasing a poultry feed mixer?

After-sales services that might be important include online support or video technical support for troubleshooting and ensuring that the supplier can provide engineers to assist with installation or training.

Is it possible to customize a poultry feed mixer according to my business requirements?

Many suppliers offer customization options such as different sizes, mixing elements, hopper configurations, and additional features to meet specific business needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4