What is Pmma

PMMA, or polymethyl methacrylate, is a transparent thermoplastic often used as a lightweight, shatter-resistant alternative to glass. Known by its common trade names like Plexiglas, Lucite, and Perspex, it is a versatile material that serves a variety of industries ranging from construction and automotive to retail and healthcare. PMMA sheets are highly valued for their clarity, UV resistance, and excellent weatherability, making them an ideal choice for outdoor applications as well as indoor decorative purposes.

The material is produced by polymerizing methyl methacrylate (MMA). PMMA works by allowing light to pass through it with minimal reflection and absorption, making it as transparent as glass. However, unlike glass, PMMA absorbs impacts without shattering, providing a safer alternative in environments where breakage and safety are concerns. Furthermore, PMMA is easily fabricated and can be cut, bent, and shaped into various forms, expanding its usage across multiple applications.

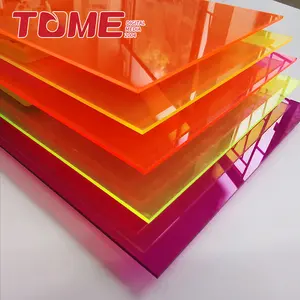

Businesses that require durable, high-clarity materials for products such as display cases, signage, skylights, or protective barriers often turn to PMMA for its desirable properties. Additionally, PMMA's ability to be tinted or colored without losing transparency makes it suitable for aesthetic applications in design and architecture. Its functionality coupled with its aesthetic versatility makes PMMA a popular choice in numerous commercial and industrial sectors.

Types of Pmma

PMMA sheets come in various types tailored to specific needs and applications:

General-purpose PMMA is the most common form used for standard applications. It offers excellent optical clarity and strength suitable for uses in displays and windows.

Impact-modified PMMA has additives that enhance its impact resistance. This type is often employed in situations where durability against physical stress is vital, such as in safety glazing or automotive parts.

Frosted PMMA provides a translucent finish that diffuses light while maintaining privacy. It's commonly used in lighting fixtures and for decorative applications where a certain level of opacity is desired.

Optical-grade PMMA is designed for the most demanding applications requiring precise light transmission and minimal optical imperfections. You'll find it in lenses, optical fibers, and scientific instruments.

Heat-resistant PMMA withstands higher temperatures than standard types without deforming. This makes it suitable for lighting fixtures and other high-temperature environments.

Each type of PMMA serves specific market segments based on its unique characteristics such as thickness, color options (Transparent, White, Clear, Black), material composition (100% virgin material), processing services available (Bending, Moulding, Cutting), surface finishes (Smooth, High gloss), and potential applications (Advertising signages, Bathroom fixtures, Hospital protective barriers).

How to choose Pmma

Selecting the right type of PMMA for your business requires consideration of several factors. Firstly, assess the application purpose—whether the PMMA will be used outdoors or indoors influences the required UV resistance and weatherability. For outdoor use cases such as signage or architectural features, UV-stabilized grades are essential.

Secondly, evaluate the mechanical requirements like impact resistance. If the application involves potential collisions or high traffic areas—like protective screens in hospitals—impact-modified PMMA would be more appropriate due to its enhanced durability.

Thirdly, consider the aesthetic aspects such as color and surface finish. If you need a particular color or finish like high gloss for advertising purposes or a frosted effect for bathroom fixtures, ensure the supplier offers these specific features.

Lastly, verify the availability of processing services. Some suppliers may provide additional services like bending or cutting to size—this could be crucial if your business lacks the equipment to perform these modifications in-house.

By integrating these considerations with the diverse selection available on Alibaba.com—including filtering options based on these exact needs—businesses can make informed decisions tailored to their specific use cases.

Best Pmma on Alibaba.com

Alibaba.com stands out as an essential marketplace for sourcing PMMA sheets for your business needs. With a vast array of options that cater to different specifications and requirements—be it for advertising materials or robust construction elements—Alibaba.com connects you with suppliers who can provide the right product for your application.

The platform's global reach ensures that you can find materials like general-purpose or specialized PMMAs from suppliers around the world. This extensive network allows businesses to compare offerings from various sources to find competitive prices without compromising on quality.

Moreover, Alibaba.com's Trade Assurance service ensures that your transactions are protected until delivery is completed—providing peace of mind when ordering materials from new suppliers. With features designed to enhance customer experience such as mobile-friendly buying processes and localized language support combined with a commitment to facilitating easy international trade solutions—Alibaba.com is an invaluable resource for businesses looking to procure high-quality PMMA sheets efficiently and effectively.

Common FAQs for PMMA

What is PMMA and what are its main uses?

PMMA, or polymethyl methacrylate, is a durable transparent thermoplastic often used as a glass substitute in applications such as display cases, signage, windows, and protective barriers.

How does PMMA compare to glass in terms of durability?

PMMA is lighter and more impact resistant than glass, making it less likely to shatter upon impact and therefore a safer alternative in many applications.

Can PMMA be used outdoors?

Yes, PMMA can be used outdoors as it has excellent weatherability and UV resistance, making it suitable for outdoor signage, skylights, and glazing applications.

What types of PMMA are available?

There are several types of PMMA available, including general-purpose, impact-modified, frosted, optical-grade, and heat-resistant varieties, each suited to different applications.

Is it possible to customize the color and size of PMMA sheets?

Yes, PMMA sheets can be produced in various colors and sizes. Suppliers may offer customization options such as tinting the material or cutting it to specific dimensions.

What processing services are available for PMMA sheets?

Common processing services for PMMA sheets include bending, moulding, cutting, and custom sizing to meet specific project requirements.

How can I determine the right type of PMMA for my application?

Selecting the right type of PMMA involves considering factors like the intended application environment (indoor or outdoor), required durability (impact resistance), aesthetic preferences (color and finish), and processing capabilities.

Are there eco-friendly options for PMMA?

While PMMA is not biodegradable, recycling programs exist for this material. Additionally, some suppliers may offer PMMA made from a percentage of recycled content.

How should PMMA sheets be maintained?

PMMA sheets should be cleaned with mild soap and water using a soft cloth. Abrasive cleaners or scrubbers should be avoided as they can scratch the surface.

What safety precautions should be taken when handling PMMA?

When handling PMMA, it is essential to wear appropriate personal protective equipment such as gloves and safety glasses to avoid injury from sharp edges or fragments.

Can PMMA be used for load-bearing applications?

PMMA is not typically recommended for load-bearing applications due to its lower strength compared to materials like polycarbonate. It is best suited for aesthetic or non-load-bearing functions.

How does temperature affect PMMA?

PMMA has a lower resistance to high temperatures compared to some other plastics. However, heat-resistant grades are available for applications involving higher temperatures.

Is PMMA resistant to chemicals?

PMMA has good chemical resistance to many substances but can be damaged by certain solvents and chemicals. It's important to check compatibility before exposure to specific chemicals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4