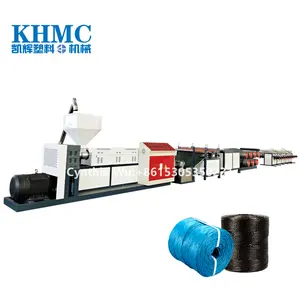

A plastic extrusion machine can increase production speed, allowing you to produce more plastic products in a shorter amount of time. It has an efficient screw design and robust cooling system to provide reliable and efficient operation, resulting in consistent and outstanding products. Extrusion machines are customizable to suit the output capacity of various industries, including construction, packaging, automotive, and consumer goods.

What are the Different Types of Plastic Extrusion Machines?

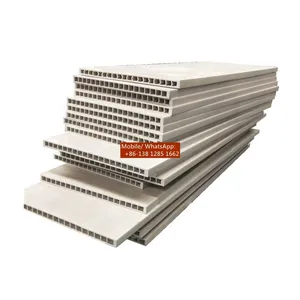

In a single-screw extruder, plastic melts and is transported using a single screw that revolves inside a cylindrical barrel. The twin screw extruder features two screws that rotate in opposing directions to mix and homogenize the plastic feedstock. Ram plastic extruders use a hydraulic piston to press plastic material into a die, making it ideal for creating large, solid objects like pipes and profiles. A cast film sheet extruder is designed for flat, thin plastic material. The blow-molding polyethylene extruder produces blow-molded products such as bottles and containers. A profile extruder creates long, continuous shapes like pipes, rods, and beams.

What are the Most Important Things to Consider When Buying a Plastic Extrusion Machine?

Keep in mind the machine's capability for production, considering its maximum output rate, the dimensions, and the types of products it is capable of producing. Verify that the polymer extruder is compatible with the materials you intend to extrude. Examine the pipe extruder output quality, including the product's dimensional precision and surface finish. Think about how simple the machine is to use and maintain and what operator training is necessary. Consider the plastic extruder manufacturer’s warranty and assistance, including the accessibility of replacement parts and technical support.

Are There Any Safety Concerns Associated With Using a Plastic Extrusion Machine?

The PVC extruder might feature heated surfaces that could cause burns and moving parts that could cause injury. When using a plastic sheet extruder, it is crucial to adhere to the correct safety protocols and rules, including using the appropriate tools and equipment, ensuring the machine is properly maintained, and wearing protective clothing. To be aware of the hazards and how to reduce them, it is equally critical that you receive proper training and education.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4