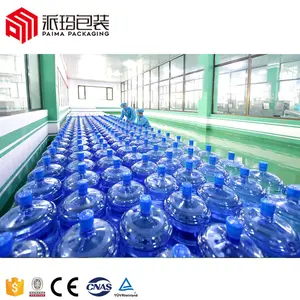

Whether you work in the beverage, chemical, or cosmetic industries, investing in a plastic bottle-making machine is a wise decision that will boost productivity and improve the overall quality of your bottled products. Plastic bottle manufacturing machines can produce top-notch bottles in a variety of shapes and sizes by utilizing modern technology.

How Do You Make a Plastic Bottle With a Bottle-Making Machine?

To ensure consistent quality, the first step is to prepare and mix the raw materials in the proper proportions. The mixed raw materials are fed into a heating barrel of a cleaner bottle-making machine and melted to form a uniform, molten state. The melted plastic is injected into a mold of the water bottle-making machine using a plunger or a screw. The mold is cooled, and the plastic solidifies into the desired bottle shape. After the bottle has cooled and solidified, excess plastic is removed with a cutting blade. Quality control checks are performed on the finished bottle to ensure it meets the desired specifications and standards. It is vital to note that the specific process may differ depending on the bottle-making machine and the desired finished product specifications.

How to Determine the Efficiency of a Plastic Bottle-Making Machine

Perform a time and motion analysis to determine how long it takes to produce a certain number of bottles. Compare this to the plastic water bottle-making machine's production capacity to determine its efficiency. Analyze the production costs per bottle, including material costs, energy, and labor costs. Also, calculate the HDPE plastic bottle-making machine's energy efficiency by measuring its energy consumption, including electricity, water, and other resources, and comparing it to the number of bottles produced.

Can Plastic Bottle-Making Machines Make Different Designs of Bottles at the Same Time?

Yes, PET bottle manufacturing machines such as multi-cavity blow molding machines can produce multiple designs in a single run. These automatic plastic bottle-making machines typically use several molds that can be swapped out to produce various bottle designs. Some advanced PET bottle-making machines can produce multiple designs simultaneously, using multiple independent stations or production lines within the same machine.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4