A plasma cutting machine can perform a melting process that which a jet of ionized gas at a temperature above 36,000F melts and blow away the material from the cut. Plasma cutting is also called plasma arc cutting. It is a piece of very useful equipment for the manufacturing, automotive, and construction industries.

What is a CNC plasma cutting machine?

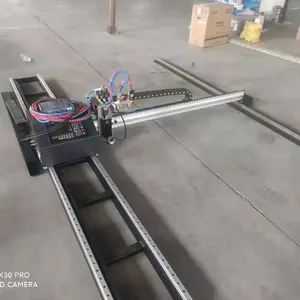

CNC stands for Computer Numerical Control. A CNC plasma cutting machine controls a plasma torch and cuts different metals directed by a computer. It gives a cleaner and more stable cut than a handheld plasma cutting tool.

What are the advantages of plasma cutting?

A plasma cutter can cut a wide range of metals, like plain carbon, stainless steel, aluminum, titanium, and nickel. It is relatively cheap for medium thickness cuts and is the most effective way of cutting medium thickness stainless steel and aluminum. It can be carried out in the water to lower the heat and minimize the noise. It can perform high-quality cutting up to 50mm thick materials and cut complex shapes with high accuracy.

How to choose a plasma cutting machine?

To operate a plasma cutting machine, it has to compress air to create the plasma. Either a built-in air compressor or an external compressed air supply can do the job. A built-in air compressor plasma cutter will be more expensive but it will save a lot of time and effort too. There are mainly three voltage options to choose from 115V, 230V, or dual voltage. 115V plasma cutters can be used at home but a generator is needed to run a 230V plasma cutter.

Portable CNC plasma cutter, plasma pipe cutter, and plasma cutting table for sale at great prices on the online platform Alibaba.com. Some suppliers have ready-to-ship plasma cutters, some offer sample orders, check them out!

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4