Introduction to Pipe Rolling Machines

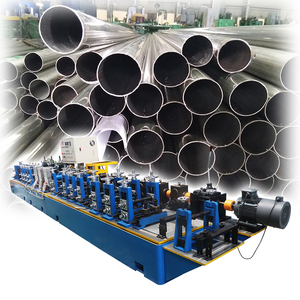

Pipe rolling machines are essential tools in the fabrication of cylindrical pipe structures. These machines manipulate metal and other materials into pipes, tubes, and coils, serving various industrial applications. From large-scale construction to intricate plumbing systems, the versatility of a pipe rolling machine is unmatched in creating uniform, precise pipes and tubes.

Types and Applications

The applications of pipe rolling machines are diverse, ranging from the creation of robust metal pipes to delicate tubing for medical devices. For heavy-duty tasks, a heavy duty pipe roller is the go-to equipment, capable of handling substantial materials with ease. In contrast, a manual pipe rolling machine offers simplicity and control for smaller-scale operations. Specialized machines, such as the down pipe roll forming machine and square pipe roll forming machine, cater to specific shapes and sizes, demonstrating the adaptability of these machines to various project requirements.

Features and Materials

A pipe roller bender is designed to work with a range of materials, including PVC, steel, and copper, ensuring that no matter the project, there's a machine capable of shaping the necessary materials. The roll pipe machine comes in different configurations, such as the single or double screw variants. While the double screw models offer increased efficiency for high-volume production, the single screw versions are suitable for less intensive tasks, balancing performance with cost-effectiveness.

Advantages of Modern Pipe Rollers

Modern pipe rolling machines, like the rolling pipe bending machine, offer enhanced precision and repeatability, which are crucial for maintaining standards in pipe fabrication. The inclusion of features like pipe grooving and pipe groovers add functionality, allowing for a more comprehensive range of operations within a single machine. For joining systems, the victaulic grooving machine provides a specialized solution for pipe-end preparation, which is essential for certain types of pipe connections.

Choosing the Right Machine

Selecting the right pipe rolling machine involves considering the material, scale, and specific requirements of the project. For instance, a roll groove machine might be necessary for projects that require grooved-end pipe connections. Meanwhile, a manual roller bending machine could be the ideal choice for workshops that handle custom, handcrafted pipes. The ridgid 975 roll groover stands out for those seeking a balance between manual control and automated efficiency.

Conclusion

In conclusion, Alibaba.com serves as a comprehensive source for businesses to find a wide array of pipe rolling machines to meet their project demands. Whether the task calls for a tubing bead roller, a pipe stand rollers, or a roll bar bender, the platform connects buyers with a diverse selection of machinery to suit any pipe fabrication need.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4