A pillow bearing is a type of bearing designed to support and fix rotating shafts. The housing of a pillow bearing is typically in the shape of a pillow or block, hence the name. Therefore, it is also known as a pillow block bearing or plummer block bearing.

The components of pillow bearings

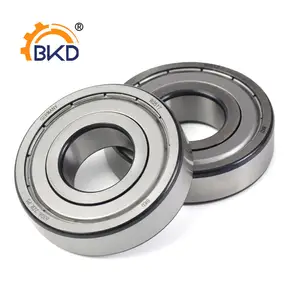

The structure of a pillow block bearing includes a housing, bearing insert, sealing device, and lubrication device. The housing is the outer shell of the pillow bearing, providing support and protection for the bearing, and is mounted on the equipment using a fixing device. The bearing insert is the core component of the pillow bearing, typically made of metal or alloy material and contains rolling elements, cages, and sealing devices. The bearing insert provides support and rotation function by fitting with the rotating shaft. The sealing device is located on the outer side of the bearing insert and is responsible for preventing dust, moisture, or other contaminants from entering the bearing. Common sealing devices include rubber seals and metal covers. The lubrication device is used to provide the necessary lubricant for the bearing to reduce friction and wear. The bearing insert usually has lubrication grooves or holes to facilitate the entry of lubricant into the bearing. The structure design of pillow bearings can be adjusted and optimized according to the specific working environments to provide appropriate performance.

The sizes of pillow bearings

Pillow bearings come in different sizes to meet various application requirements. For example, a 1/2 pillow block bearing refers to a bearing insert with an inner diameter of 1/2 inch (12.7 millimeters). It is suitable for smaller load applications, such as small transmission devices, hand tools, or light-duty machinery. On the other hand, a 5/8 pillow block bearing has an inner diameter of 5/8 inch (15.88 millimeters) and is suitable for medium load applications, such as conveyor systems. For small machinery or precision instruments, a pillow bearing with a 1-inch (25.4 millimeters) inner diameter is a common choice. It provides stable bearing support and alignment. For larger industrial equipment or heavy-duty applications, a 2-inch pillow block bearing (50.8 millimeters) is suitable. The larger size pillow bearing offers higher load capacity and stability. It should be noted that the above sizes are just examples, and the actual dimensions of pillow bearings may vary depending on the manufacturer and model. When selecting pillow bearings, it is important to consider specific application requirements and equipment specifications to choose the appropriate size and specifications of pillow bearings.

Applicable fields of pillow bearings

Pillow bearings are widely used in various fields. For example, in agricultural machinery, pillow bearings are used in equipment such as tractors, harvesters, and seeders. In mining equipment, pillow bearings are commonly found in equipment such as conveyor belts, crushers, and screening machines, as they can withstand high loads and impact loads. In the construction machinery industry, pillow bearings are widely used in equipment such as concrete mixers, tower cranes, and hoists to meet high-strength and high-frequency work requirements. In the textile machinery field, pillow bearings are commonly used in equipment such as spinning machines, weaving machines, and printing and dyeing machines to ensure the quality and production efficiency of textiles. Additionally, pillow bearings are widely used in food processing equipment such as mixers, conveyors, and packaging machines.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4