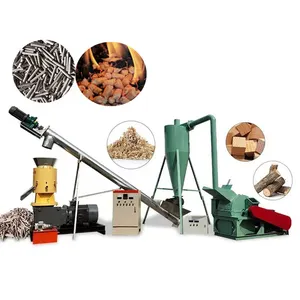

A pellet making machine is an essential piece of equipment used in various industries. This machine is primarily used to convert raw materials into small, compact pellets. These pellets are then used for different applications, depending on the type of raw material used.

Types and uses of pellet making machines

There are many types of pellet making machines available, each designed to cater to different needs. A pellet mill for wood is commonly used in the forestry industry to convert wood chips and sawdust into wooden pellets. On the other hand, a plastic pellet making machine is used in the recycling industry to turn waste plastic into reusable pellets. For small scale usage, a small pellet mill is the ideal choice. This type of pellet mill is compact, easy to operate, and suitable for personal use or small businesses. For larger scale production, a pellet mill machine or a pellet press machine is more appropriate.

The applications of pellet making machines are varied and wide-ranging. For instance, a pellet maker for pellet stove is used to create fuel pellets for heating homes. These machines take biomass like wood chips or agricultural waste and convert them into energy-efficient, eco-friendly fuel. In the industrial sector, pellet making machines are used to create pellets from raw materials such as metal, plastic, and wood. These pellets are then used in various manufacturing processes. A pellet maker machine can also be used in the animal feed industry, creating nutrient-dense feed pellets for livestock.

Features and advantages of pellet making machines

Pellet making machines come with a range of features that enhance their usability and efficiency. They are typically equipped with a die and roller system, which is responsible for compressing the raw material into pellets. The machine's design ensures that the produced pellets are of uniform size and shape. Many pellet making machines also come with adjustable settings, allowing users to alter the size and density of the pellets produced. This feature is particularly useful in industries where the size and density of pellets play a crucial role in the final product's quality and performance.

Pellet making machines offer numerous benefits. Firstly, they allow for the efficient utilization of waste materials. Whether it's wood waste in the forestry industry or plastic waste in the recycling industry, pellet making machines help turn these materials into valuable resources. Secondly, these machines help reduce the cost of raw materials. By converting waste into usable pellets, businesses can lower their material costs. Lastly, the pellets produced by these machines are compact and easy to store and transport, making them an ideal choice for industries that require large volumes of material to be moved or stored.

Materials used in pellet making machines

Pellet making machines are typically made from durable materials to ensure their longevity and performance. The main body of the machine is usually constructed from robust steel, while the die and rollers are often made from alloy steel or stainless steel. These materials ensure that the machine can withstand the rigors of continuous operation and are resistant to wear and tear. A pellet making machine is a versatile and beneficial piece of equipment used in various industries. Whether it's turning waste into valuable resources or producing pellets for various applications, these machines are crucial for many businesses.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4