A parts washer is a piece of equipment used to clean parts and components in industries such as automotive, manufacturing, and maintenance. It typically consists of a tank or basin filled with a cleaning solution, a pump to circulate the solution, and various features to aid in the cleaning process. Parts washer pump can be categorized as manual, automatic, or enclosed systems, depending on how they are operated and whether they are open or closed during the cleaning process. The choice of a parts washer depends on the specific cleaning requirements and the volume of parts to be cleaned.

Features and Components of a Parts Washer

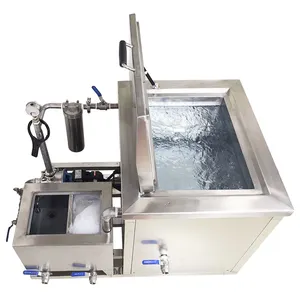

Parts washer solvent typically has a tank or basin where the cleaning solution is held. This is where the parts are submerged or sprayed for cleaning. The cleaning solution used in harbor freight parts washer can vary depending on the type of contaminants being removed and the materials of the parts. It may be a solvent-based solution, water-based detergent, or other specialized cleaning agent. A pump is used to circulate the cleaning solution through the system. It helps in agitating the solution and ensuring that it reaches all parts of the components being cleaned. Industrial parts washer has a heating element to warm the cleaning solution. Heating the solution can improve its cleaning effectiveness, especially for removing stubborn grease and oils. Parts washer cabinet may have spray nozzles or brushes to apply the cleaning solution to the parts. Spray nozzles are common in automatic or enclosed parts washers, while manual parts washers may have brushes for scrubbing. Many parts washers are equipped with a filtration system to remove contaminants from the cleaning solution. This helps extend the life of the solution and maintain its cleaning efficiency. Some advanced parts washers may include a drying feature to remove any remaining moisture from the cleaned parts. This is particularly useful to prevent corrosion in metal components.

Benefits of Using a Parts Washer

Cuda parts washer uses powerful cleaning solutions and spray systems to remove dirt, grease, oil, and other contaminants from parts. This results in a more thorough and efficient cleaning process compared to manual methods. Using a parts washer fluid can significantly reduce the time and labor required to clean parts. Instead of manually scrubbing and soaking parts, they can be placed in the parts washer and left to clean while employees can focus on other tasks. Parts washer heater provides consistent cleaning results, ensuring that parts are cleaned to a specific standard every time. This is especially important in industries where cleanliness is critical for proper functioning or safety. Regular cleaning of parts using a parts washer helps to remove contaminants that can cause equipment damage or malfunctions. By keeping parts clean, the lifespan of equipment can be extended, reducing the need for costly repairs or replacements. While the initial investment in an automatic parts washer may be higher than manual cleaning methods, the long-term cost savings can be significant. Reduced labor costs, extended equipment lifespan, and decreased need for cleaning supplies all contribute to cost savings over time. Overall, a parts washer offers numerous benefits in terms of efficiency, cost savings, environmental impact, and workplace safety. It is a valuable tool for industries that require regular cleaning of parts and components.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4