The nickel strip for battery is an indispensable component in the construction of battery packs, acting as a vital electrical conduit and contributing to structural integrity. Its significance lies in its ability to bolster the performance and dependability of battery packs utilized in various devices.

Types and Characteristics of Nickel Strips

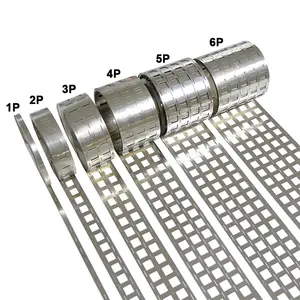

The spectrum of nickel strips encompasses a variety of types, each designed with unique attributes to suit particular uses. The pure nickel strip is distinguished by its exceptional purity, typically surpassing 99.6%, making it ideal for applications where low resistance and high conductivity are paramount. This purity is especially advantageous in high-drain scenarios that prioritize energy efficiency. On the other hand, the nickel plated steel strip is a more economical alternative, offering adequate conductivity and superior mechanical strength, apt for consumer electronics where cost considerations may outweigh the need for peak performance. For precise alignment with common battery models, the nickel strip for 18650 battery welding is crafted to exact specifications, ensuring a snug fit and reliable electrical contact with cell terminals. The assortment also includes specialized forms such as 2p nickel strip and nickel strip tape, catering to bespoke battery configurations and intricate assembly demands.

Structure and Operation of Nickel Strips

The architecture of a nickel strip is carefully devised to optimize its role within a battery pack. Uniformity in cross-sectional area is a hallmark of these strips, critical for even current distribution and thus essential for the battery cells' efficiency and durability. In battery assembly, the nickel strip for battery welding must be produced with meticulous attention to detail, ensuring smooth edges to avert damage to battery casings during welding. The operational duties of these strips are manifold: they must efficiently conduct electricity, adapt to the volumetric changes of battery cells throughout charge cycles, and withstand environmental and chemical wear over the battery pack's lifespan.

Materials and Properties

The selection of materials for nickel strips is guided by the requisite electrical and mechanical characteristics. Ni200, or pure nickel, is frequently chosen for its superior electrical conductivity, which is critical in minimizing energy dissipation within the battery pack. Its resistance to corrosion is equally vital, guaranteeing the strip's durability in the often-corrosive settings of battery operation. Where cost is a deciding factor, a nickel plated steel strip presents a balanced option, delivering respectable electrical performance and enhanced mechanical resilience, beneficial in scenarios where durability is as crucial as electrical efficacy.

Business Usages and Applications

Nickel strips are employed in an extensive range of commercial applications, from crafting battery packs for consumer electronics to developing energy storage systems for renewable sources. In the automotive realm, nickel strips for battery packs are essential in fabricating electric vehicle batteries, where their dependability and high conductivity are vital for the vehicle's performance and safety. Similarly, in portable electronics, these strips facilitate the creation of compact, high-efficiency batteries that power an array of devices, from smartphones to laptops, ensuring consistent reliability and performance.

Functions and Tasks

The principal role of nickel strip is to forge a stable, low-resistance electrical link among the cells within a battery pack. This function is dynamic; the strip must be sufficiently pliable to accommodate the cells' expansion and contraction during charge cycles, maintain steady conductivity across temperature variations, and endure wear over numerous battery cycles. In the realm of battery welding, the nickel strip for battery welding must also enable a robust, enduring connection with cell terminals, safeguarding the electrical bond over the battery pack's lifetime.

Features and Unique Selling Points

High-caliber nickel strips are marked by their consistency in thickness and breadth, crucial for uniform performance across the battery pack. The pure nickel strip stands out for its high purity, which directly correlates to reduced electrical resistance and heightened efficiency, making it the preferred option for demanding applications. Moreover, certain strips are tailored with specific enhancements like pre-punched tabs or notches, which can significantly expedite the battery assembly process, thereby cutting down on production time and costs.

Benefits and Positive Outcomes

Proper selection and application of nickel strips in battery assembly can yield numerous advantages. These include improved longevity of battery packs, increased energy density, and a diminished risk of battery pack failure. For enterprises, this translates to more dependable products, fewer warranty claims, and heightened consumer satisfaction. In applications where performance is critical, such as in advanced electronics or electric vehicles, the advantages of employing a pure nickel strip may also be seen in enhanced device operation time and reduced charging intervals.

How to Use and Operate Effectively

To effectively utilize nickel strips, a thorough understanding of the battery pack's specifications and demands is essential. For instance, when employing a nickel strip for 18650 battery welding, precision tools are necessary to achieve a clean and robust weld, crucial for the integrity of both the strip and the cell. The choice of strip should be informed by the battery pack's current capacity and the environmental conditions it will encounter.

How to Choose the Right Nickel Strip

Selecting the suitable nickel strip entails assessing the battery's intended use. Factors to consider include the peak current draw, operational environmental conditions, and the desired cycle life of the battery pack. For high-drain uses, a pure nickel strip is often essential due to its superior electrical properties, whereas for more budget-conscious applications, a nickel plated steel strip may suffice.

How to Maintain Nickel Strips

The upkeep of nickel strips within battery packs primarily involves preserving the integrity of the welded joints and averting corrosion. Periodic inspections can detect issues early, and proper storage conditions, such as a low-humidity environment, can extend the lifespan of the nickel strips.

In conclusion, the nickel strip for battery may be a modest component, yet its influence on the efficacy and dependability of battery packs is substantial. Alibaba.com provides businesses with an extensive selection of nickel strips, ensuring they can secure the exact specifications needed to power their products with efficiency and reliability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4