What is Film Blowing Machine For Small-scale Production

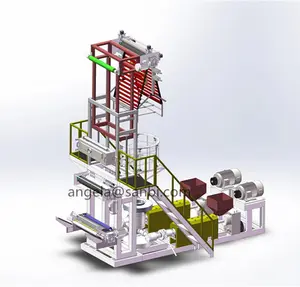

Film blowing machines are a type of equipment used in the plastic manufacturing industry to produce plastic films, which are thin sheets of polymer material. These machines are essential for companies that require a reliable and efficient method to produce large volumes of plastic film for products such as food packaging, agricultural mulches, and industrial packaging. The film blowing process involves melting plastic pellets and passing the molten material through a circular die to create a continuous tube of plastic. This tube is then inflated with air to the desired size, thickness, and width, while being cooled to set its shape.

The primary users of film blowing machines range from small-scale entrepreneurs looking to start a plastic film production line to large corporations with extensive manufacturing plants requiring sophisticated equipment to meet high-volume production demands. These machines serve as the backbone for businesses that aim to deliver quality film products at scale while maintaining cost-efficiency.

The working principle of film blowing machines is based on the extrusion of plastic material. The process starts with the feeding of plastic pellets into a hopper, which is then melted in an extruder. The molten plastic is forced through a circular die to form a continuous tube of plastic. This tube is then inflated to the desired size by introducing air into the bubble-like structure. As it inflates, the material gradually cools and solidifies into the film. The speed of the inflation and the cooling method are critical variables that can be adjusted to control the thickness and properties of the final film.

Types of Film Blowing Machine for Small-Scale Production

The market offers several types of film blowing machines tailored to meet the diverse needs of different businesses:

-

Standard Blown Film Machine: This type is commonly used for producing general-purpose packaging films. It can create single-layer films from materials like LDPE, HDPE, or LLDPE. These are suitable for simple applications such as grocery bags or shrink wraps.

-

Multi-Layer Co-extruded Film Blowing Machine: This machine can produce films with multiple layers, offering enhanced mechanical properties compared to single-layer films. It’s often used in more demanding applications where better barrier properties are required.

-

Stretch Film Machine: Designed to produce films that can be stretched in both directions, this type is ideal for pallet wrapping. Stretch films are often used in logistics to secure and protect products during transportation.

-

Heat Shrink Film Machine: Used to produce films that shrink tightly around items when heat is applied, this machine is essential for creating tamper-evident packaging and is commonly used in the pharmaceutical and cosmetic industries.

-

Hot Melt Applicator Machine: After the film is extruded, adhesive is applied to one side before the film is cooled in a water bath. The resulting film is suitable for applications requiring bonding, such as lamination in flexible packaging.

How to choose Film Blowing Machine For Small-scale Production

Selecting the right Film Blowing Machine is critical for businesses looking to produce high-quality plastic films. When considering a purchase on Alibaba.com, it's important to assess several factors:

-

Production Volume: Determine the quantity of film you need to produce. For small-scale or infrequent production runs, you might consider a standard or mini film blowing machine. For larger volumes, consider a multi-layer or rotary die machine.

-

Film Type and Application: Identify the type of films you intend to produce and their intended applications. Different types of machines are optimized for specific types of films—LLDPE for general packaging, LDPE for heavy-duty or agricultural applications, or HDPE for high-density bags.

-

Local Service Location: Consider where you are located or where you can access technical support. Having a local service location can be beneficial for ongoing maintenance and support needs.

-

Automation Level: Depending on your labor availability and budget constraints, select a machine with an appropriate level of automation—ranging from semi-automatic to fully automatic—to maximize productivity without compromising quality.

-

Energy Consumption: Opt for a machine that offers energy-saving features like an energy-saving mode or adjustable temperature controls, which can reduce operational costs over time.

By taking these considerations into account when browsing Alibaba.com's extensive selection of Film Blowing Machines, businesses can find equipment that aligns with their specific production needs.

About Film Blowing Machine For Small-scale Production on Alibaba.com

Alibaba.com stands as a leading marketplace for businesses across the globe seeking reliable film blowing machines tailored to their unique production needs. With an extensive range of options from numerous suppliers, Alibaba.com provides businesses with the flexibility to find machines that meet their specific requirements without compromising on quality or efficiency. The platform's emphasis on connecting buyers with reputable suppliers ensures that businesses can invest in their machinery with confidence.

Alibaba.com's commitment to streamlining international trade is evident through its user-friendly interface and services like Trade Assurance that safeguard payments until order fulfillment. This focus on security and customer satisfaction underpins Alibaba's reputation as a trusted platform for B2B transactions.

Whether a business is looking to expand its operations or streamline its production process, Alibaba.com offers a pathway to acquiring film blowing machines that can help facilitate growth and enhance productivity. With suppliers from various regions offering a multitude of machine types and features, Alibaba.com simplifies the procurement process by providing detailed information and support at every step.

Common FAQs for Film Blowing Machine For Small-scale Production

What is the main difference between LDPE and HDPE films?

The main difference between LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene) films is in their material properties. LDPE is more flexible and has a lower tensile strength compared to HDPE, which is stiffer and more impact-resistant.

How do I determine the thickness of the film I need for my application?

To determine the appropriate thickness for your film, consider the application's requirements such as protection, flexibility, barrier properties, and the specific use of the film in industrial settings.

What does the term 'blow film' mean in the context of film blowing machines?

'Blow film' refers to the process of creating a continuous plastic film by blowing air into a bubble that is then cooled and shaped into a film roll.

Are there different types of film blowing machines for different polymers?

Yes, there are various types of film blowing machines designed to process different polymers, each with specific features tailored to the polymer's characteristics and the intended application of the film.

How do I choose between semi-automatic and automatic film blowing machines?

The choice between semi-automatic and automatic film blowing machines depends on your production scale and the level of automation you require. Semi-automatic machines offer more control and are good for smaller scale operations, while automatic ones are ideal for high-volume production lines.

What should I consider regarding after-sales service when purchasing a film blowing machine?

Consider whether the supplier offers after-sales services such as engineers for service machinery overseas, online support or video technical assistance, and field maintenance and repair services to ensure long-term operational efficiency.

How do I know if a film blowing machine is suitable for food packaging applications?

Check the specifications of the machine for compliance with food-grade standards and certifications. Additionally, ensure that the materials used in the machine's construction are non-toxic and do not contaminate food products.

Can film blowing machines be customized based on specific requirements?

Yes, many suppliers offer customization options for film blowing machines based on specific application needs. Customizable features may include film width, thickness, material composition, machine speed, and additional functionalities.

What safety precautions should be considered when operating a film blowing machine?

Operators should be trained on safe handling practices and wear appropriate personal protective equipment (PPE) to prevent accidents during the operation of a film blowing machine.

How does environmental sustainability factor into the choice of a film blowing machine?

Environmental sustainability is a significant consideration when choosing a film blowing machine. Look for systems that emphasize energy-saving operation, reduce waste in production processes, and use materials that are recyclable or have a lower environmental impact.

What is meant by 'easy to operate' in the context of film blowing machines?

'Easy to operate' refers to machines that offer intuitive controls, minimal setup time, and straightforward adjustments. This factor is crucial for quick turnaround times and ease of use within industrial settings.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4