Top categories

Prefabricated Buildings

Countertops, Vanity Tops & Table Tops

Building & Industrial Glass

Mosaics

Metal Building Materials

Multifunctional Materials

Ladders & Scaffoldings

Mouldings

Corner Guards

Decorative Films

Formwork

Other Construction & Real Estate

Soundproofing Materials

Timber

Waterproofing Materials

Building Boards

About products and suppliers

Introduction

In the realm of interior design and architecture, the smallest details often make the most significant impact. One such detail is the metal edge trim, a seemingly minor component that can dramatically enhance a space's aesthetic appeal and functionality. This article delves into the world of metal edge trim, exploring its various types, benefits, and applications. We'll discuss different materials like stainless steel, aluminum, and brass, and how they contribute to the overall look and durability of a project. Whether you're a professional designer or a DIY enthusiast, understanding the role of metal edge trim can help you elevate your design game.

Understanding Metal Edge Trim

Metal edge trim, also known as a profile, is a finishing edge positioned along the borders of a tile field during installation. It's bonded under the tile with an anchoring leg, set into the same thin-set mortar as the tile, becoming a permanent part of the assembly. This trim adds a layer of protection to the tile, preventing chipping or cracking, especially in high-traffic areas. It also enhances aesthetics, with a variety of materials, colors, finishes, and shapes available, providing numerous design options.

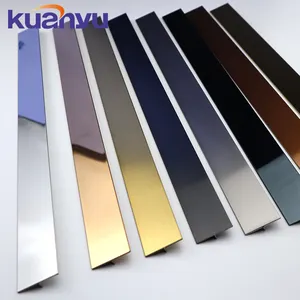

Types of Metal Edge Trim

Metal Trims and Transitions are designed to go from surface to surface, providing a finished look to your project. They are perfect for tub or shower edges, stairs, and even to finish the edges of a floor. The types of metal trims include L-Angle, Schiene/ Jolly, Reno-T, Reno-U, Reno-TK, R-Shape, Q-Shape for walls, and L-Shape, Q-Shape, T-Shape, U-Reducer for floors. For counters, an L-Shape, R-Shape, Q-Shape or RS-Step is recommended. They protect the tile from chipping and lessen the need for caulk, offering a clean and modern look.

Stainless Steel Trim

Stainless steel edge trim is a popular choice in floor decoration due to its numerous advantages. It is firm, does not deform under external force, and is easy to install. Moreover, stainless steel is corrosion-resistant, ensuring its longevity even though the initial cost might be slightly higher than other materials like PVC and aluminum alloy. Another significant advantage is its resistance to pollution, making it easy to clean and maintain. These attributes make stainless steel edge trim a valuable asset in the field of decoration.

Aluminum Trim

Aluminum edge trim is a versatile addition to any project, thanks to its malleability, pliability, and corrosion-resistant properties. It not only adds an aesthetically pleasing accent but also protects surfaces from wear and tear. It can be customized to fit various design styles, from retro to modern. Its applications are endless, including countertop projects, vintage kitchen remodeling, bar nosing, and more. Anodized aluminum edge trim also protects flooring in high-traffic areas, acting as a decorative edging for stairs and podiums. It's a cost-effective way to add style to your project.

Brass Trim

Brass edge trim is a popular choice for many applications due to its durability and aesthetic appeal. Various models are available, each with different thicknesses and lengths. Brass edge trim offers a timeless elegance to any project, making it a preferred choice for many.

Benefits of Using Metal Edge Trim

Metal edge trim, often used in landscape edging, is renowned for its excellent strength, particularly when made from steel. It can withstand ground movement and retain its shape even when knocked. Its thinness allows for subtlety, creating clean lines without being obtrusive. Unlike wood or brick, metal doesn't absorb water, preventing rot and maintaining its shape. High-quality metal edge trim, such as those made from steel or aluminum, can last over 20 years, outlasting wooden edging. Despite its durability, most forms of metal edge trim are easy to install.

Durability and Longevity

Metal tile trim offers a high-quality finish that is unmatched in durability. Ideal for high traffic areas or locations that come into contact with chemicals, metal trim won't wear or corrode easily. This makes it a long-lasting solution for your tiling needs. Despite common misconceptions, metal trims offer a variety of finishes, colours, and materials to match any room, coordinating with fixtures and fittings to create a cohesive, slick look.

Modern Aesthetic Appeal

Choosing the right aesthetic for your architectural project is more complex than it may seem. There are many metals to choose from, and each provides its own unique aesthetic. For instance, copper oxidizes and ages beautifully, turning seafoam green over the years. Brass, with the right amount of zinc mixed in, closely resembles gold. Stainless steel's clean, shiny appearance makes it a wonderful addition for many professional settings. Galvanized steel, with its striking spangles, is popular in modern and industrial-style architecture. The type of metal you choose for your application will depend on its environment and surrounding aesthetics.

Easy Maintenance

Maintaining metal edge trim is straightforward. Regular cleaning helps to keep it looking new, while careful inspection can identify any potential damage early. Avoid abrasive contact to prevent scratches and ensure proper sealing for waterproofing. Regular maintenance routines, including grout maintenance, can extend the lifespan of your metal edge trim. In case of complex issues, don't hesitate to seek professional assistance.

How to Install Metal Edge Trim

Installing metal edge trim, also known as eave trim or drip edge, is a crucial step in metal roofing. It's typically the first piece of trim to be installed. The purpose of this trim is to divert rainwater off the roof and away from the fascia, ensuring a clean look and preventing water from getting underneath your roof. The installation process involves overlapping the eave trim from left to right across the roof. Always consult the manufacturer's installation guide and comply with local building codes. Remember, a well-installed metal edge trim enhances the longevity and aesthetics of your roof.

Selecting the Right Metal Edge Trim for Your Project

Selecting the right metal edge trim is crucial as it provides a clean, professional frame for your tiles. It's produced in various materials like aluminum, stainless steel, and brass. The choice depends on how these options complement your tiles, the trim style availability, and the space's purpose. For instance, rust-proof materials like aluminum are necessary for areas exposed to water, while durable materials like stainless steel are ideal for high-traffic areas. Remember, the wrong fit means the trim won’t stay flush with the tile, creating a messy look. So, choose a trim size that is one-sixteenth to one-eighth of an inch deeper than the tile.

Conclusion

In conclusion, metal edge trim is a versatile and functional design element that can significantly enhance the aesthetic appeal and longevity of a project. From stainless steel to aluminum and brass, the variety of materials available allows for a wide range of design possibilities. Not only does it provide a clean, professional finish to tiles, but it also offers excellent durability, easy maintenance, and a modern aesthetic appeal. Selecting the right metal edge trim for your project is crucial, considering factors such as the type of tile, the purpose of the space, and the desired aesthetic. With the right choice and proper installation, metal edge trim can be the secret ingredient that brings a modern and polished look to your design.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4