Wheat Flour Mill Plant European Standards 50T/24H Flour Mill Machine Wheat Flour Processing Machinery Plant

Corn Powder Packing Machine 5kg 15kg 25kg 50kg Pellet Nuts Pet Food Packing Machine Big Bag Packing Machine

CNC Center Machine Vmc1370 Wholesale Suppliers Cnc Milling Machine

Cast Iron Commercial Manual Coriander Corn Cob Crop Dried Fruit Grinder Flour Milling Machine

Best 15tpd-20tpd Wheat Milling Machine Flour Mill Maize Flour Milling Machine

Factory Direct Sale Maize Grits Making Machine Corn Grits Grinding Machine For Kenya

QT corn grits milling machine Automatic Africa maize grit mill corn grinding milling machine prices

Grinding corn mill maize milling machine price in south Africa 5ton 24h

Automatic Africa maize flour mill corn milling machine prices

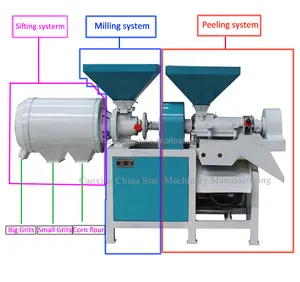

Posho Mill Corn Grits Semolina Make Sift Small Scale Maize Meal Grind Milling Machine Price for Sift in Kenya

30 ton per day commercial maize flour milling machines prices

30 tons Industrial Maize Corn Plant Meize Flour Grits Milling Mill Machine price maize milling machine

30tpd maize flour milling machine MAIZE MILLING MACHINE /corn mill prices/posho mill

Best price Maize milling machine corn grits making machine

High capacity factory direct price electric maize milling machine

Automatic Africa maize flour mill corn grinding milling machine prices

HNLY new mazie flour making machine with price/maize flour milling machine

Industrial Flour Milling Machine Price Plant Corn Maize Wheat Flour Mill Machinery

Factory price wheat grade 1 maize flour milling machine corn grinders mill machine with prices/commercial flour mill pakistan

Maize Roller Mill/wheat Flour Mill Price Small-size Corn Milling Machine, Corn Flour Mill Machine Wheat Flour Producing Machine

Industry Small Scale Automatic Roller Flour 5 Ton Corn Wheat Flour Mill Maize Milling Machine Price

Heavy duty small maize flour mill / maize milling machine factory direct price / corn mill machine

Hot maize corn cassava powder milling machine price grain chilli spice flour grinding mill machine

stainless steel automatic small corn wheat small flour mill machinery prices small scale maize milling machine

Corn Mill machine Automatic africa maize flour mill corn grinding milling machine prices

super fine white maize milling machine corn flour powder making grinding machine prices

Maize flour milling machine/corn roller mill/wheat flour mill price

DAWN AGRO Mini Maize Flour Mill Milling Machine Grain Grinding Fine Spice Powder Making Machinery Price

Small Electric Corn Maize Milling Grinding Machine Price For Sale In Tanzania

Industry Small Scale Automatic Roller Flour Corn Wheat Flour Mill Maize Milling Machine Price

cheap price maize milling machine

800-1000kg/h maize flour milling machines grinding machine for corn grits corn milling machine grinder maize grits making price

Electric Industrial maize flour mill corn grits grinding milling machine price

Best Price Grain Processing Machine Mini Maize Flour Milling Machines

20 ton per day small scale corn maize mill milling machine prices of flour mills

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4