Honeycomb Machine: An Overview

The honeycomb machine stands as a pivotal equipment in the realm of paper production, particularly in the fabrication of honeycomb core materials. These machines are engineered to meet the diverse needs of various industries, ranging from packaging to construction. The versatility of a honeycomb paper machine allows for the production of lightweight yet sturdy honeycomb paper, which is increasingly sought after for its balance of strength and sustainability.

Types and Applications

There are multiple types of honeycomb production machinery, each tailored for specific applications. The honeycomb paper roll making machine is designed for creating continuous honeycomb paper rolls, which are essential in packaging and logistics. For more intricate tasks, the honeycomb die cutter is utilized to precision-cut honeycomb materials for use in industries that require exact shapes and sizes, such as automotive and furniture manufacturing. The adaptability of these machines extends to the realm of energy, where a honeycomb briquette machine plays a significant role in producing solid fuel from paper waste.

Features and Materials

Modern honeycomb making machines are constructed with an emphasis on durability and efficiency. They are capable of handling a variety of materials, including recycled paper, which contributes to their eco-friendly profile. Features may include advanced control systems for precise operation and modular designs that allow for easy maintenance and part replacement. The construction of these machines often involves robust materials that withstand the rigors of continuous operation while ensuring the longevity of the equipment.

Advantages of Honeycomb Machinery

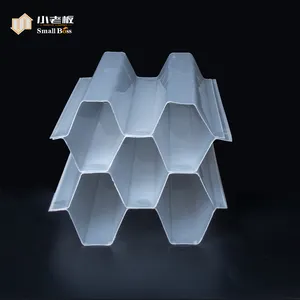

Utilizing a honeycomb machine in production brings forth numerous advantages. The honeycomb structure produced is renowned for its strength-to-weight ratio, providing exceptional protection while minimizing material use. This not only reduces costs but also lessens the environmental impact. Moreover, the flexibility of machines, such as the honeycomb packaging machine, allows for customization in honeycomb cell size and shape, catering to specific packaging requirements.

Innovations in Honeycomb Technology

Innovation in honeycomb technology has led to the development of specialized equipment like the honeycomb panel for laser engraver and the honeycomb for laser cutter. These advancements have expanded the use of honeycomb materials into precision cutting and engraving, benefiting sectors that require detailed work, such as the arts and electronics industries. Additionally, the integration of CNC technology has given rise to honeycomb CNC machines, enhancing the precision and automation of honeycomb production.

Choosing the Right Honeycomb Machine

Selecting the appropriate honeycomb machine is crucial for optimizing production. Factors to consider include the intended application, material compatibility, and the specific features that align with production goals. Platforms like Alibaba.com facilitate the connection between businesses and a diverse array of suppliers, offering a spectrum of honeycomb production solutions to meet various industrial needs without the direct promotion of any single brand or price point.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4