What is High-density Fiberboard

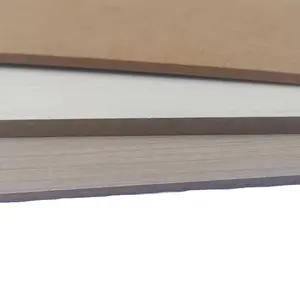

High-Density Fiberboard, often abbreviated as HDF, is a versatile and durable material commonly used in the construction and furniture industries. It is made by compressing wood fibers into a dense panel, with the help of resins and wax. The result is a smooth, hard surface that is more uniform and less porous than traditional wood materials, making it an excellent choice for applications where a high degree of precision and a specific surface finish is desired.

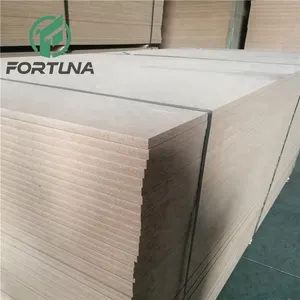

This type of fiberboard is engineered for a wide range of users, from contractors and furniture manufacturers to interior designers and DIY enthusiasts. It serves as a core material for various commercial and residential products, including shelving units, cabinets, doors, and furniture components. The density of high-density fiberboard allows for a sturdy, reliable support structure that can withstand heavy loads or substantial impact.

The manufacturing process of HDF involves several steps. First, wood fibers are extracted from softwood and then mixed with a synthetic resin. This mixture is then formed into boards, which are compressed under high pressure. The boards' density is increased further by additional layers of wood fibers and resins, making it stronger and more durable. To finish, the material is sanded to a smooth surface and often coated with a thin layer of melamine or laminate to provide moisture resistance and aesthetic appeal.

Types of High-Density Fiberboard

The market offers a spectrum of high-density fiberboards, each suited for particular applications based on their material composition and properties. For instance:

-

MDF (Medium-Density Fiberboard): This type is known for its uniform density and smooth finish. MDF is often used in cabinetry and furniture due to its strength and ability to take finishes well.

-

HDF (High-Density Fiberboard): HDF is similar to MDF but typically denser, making it suitable for applications requiring more structural rigidity, such as interior door panels or wall paneling.

-

Hardboard: Hardboard is another type of high-density fiberboard that is often used as a backing for furniture and display units due to its strength and impact resistance.

-

Perforated Board: These are high-density fiberboards with regularly spaced holes that reduce weight and cost while maintaining strength. They are commonly used in speaker boxes and furniture where acoustics are a consideration.

-

Flexible Board: A newer addition to the market which is engineered to be more bendable than traditional fiberboards, making it ideal for curved surfaces or designs that require flexibility.

-

Moisture-Resistant Board: Specifically designed to resist moisture, these boards are suitable for environments like bathrooms and kitchens where there is the risk of water exposure.

How to choose High-density Fiberboard

Selecting the right High-Density Fiberboard (HDF) for your business involves understanding the specific needs of your project and how different types of HDF can meet those requirements effectively. When considering an HDF purchase on Alibaba.com, here are some key factors to ponder:

-

Application Needs: Identify the intended use for the HDF. If it's for indoor furniture, moisture-resistant HDF may be crucial. For outdoor applications like decking or cladding, ensure that the product has been treated for weather resistance.

-

Formaldehyde Emission Standards: Assess the level of formaldehyde emissions you can tolerate. Different standards like E1 or E2 indicate the amount of formaldehyde released by the board, with E1 having a lower emission rate than E2.

-

Design Style: Consider the aesthetic style that aligns with your project's design requirements—be it modern, minimalist, or traditional. Alibaba.com offers a range of veneer finishes that can complement various design styles.

-

Material Composition: The base material (wood fiber or plant fibers) can affect the performance and appearance of the HDF. Choose a material that meets your criteria for both functionality and beauty.

-

Grade Quality: Opt for a grade that reflects the quality you desire in your finished product. First-class grades may offer better strength and durability which could be important for your project's success.

About High-density Fiberboard on Alibaba.com

Alibaba.com stands out as an international marketplace connecting businesses with a vast selection of High-Density Fiberboards suited for an array of applications. With over two decades of facilitating global trade, Alibaba.com has established itself as an invaluable resource for businesses seeking quality materials that meet their specific requirements without compromising on design flexibility or cost-effectiveness.

The platform's extensive network of suppliers ensures that you can find products tailored to your needs—whether it's eco-friendly options for environmentally conscious projects or waterproof variants for moisture-prone environments. Moreover, Alibaba.com simplifies the procurement process with user-friendly search capabilities that help you filter through products based on application areas like office spaces or kitchen cabinets and even specific project solution capabilities such as 3D model design support.

Alibaba.com's commitment is evident through services like Trade Assurance that protect your payments until delivery is confirmed. Their global reach also opens doors to a world of design styles and functional requirements that you may not readily find in your local market. By choosing Alibaba.com as your sourcing platform for High-Density Fiberboards, you gain access not only to quality materials but also to a seamless trade experience that empowers your business's growth wherever your projects may lead you.

Common FAQs for High-density Fiberboard

What is the primary difference between MDF and HDF?

MDF (Medium Density Fiberboard) is an engineered wood product that is generally used for indoor furniture and cabinetry, while HDF (High Density Fiberboard) is more water-resistant and suitable for environments with high humidity or frequent contact with water.

How does the formaldehyde emission class affect my choice of HDF?

Formaldehyde emission classes indicate the levels of formaldehyde released from the HDF. E0 signifies low emissions and is suitable for furniture and other indoor applications, while E1 to E2 are higher in emissions and may be used in areas with strict formaldehyde regulations.

What should I consider when selecting the thickness of high-density fiberboard for my project?

The thickness should be chosen based on the specific application of the HDF. Thicker boards are generally more durable and suitable for structural purposes, while thinner sheets are adequate for decorative elements or where weight is a consideration.

Can high-density fiberboard be painted or stained?

Yes, high-density fiberboard can be painted or stained. However, the method of staining or painting HDF will depend on the specific type and quality of the board and the desired finish.

Is high-density fiberboard water-resistant?

High-density fiberboards are not inherently waterproof. However, they can be made water-resistant with additional treatments or coatings that protect the surface from moisture.

How do I ensure the high-density fiberboard I purchase meets industry standards?

To ensure that the high-density fiberboard meets industry standards, look for products that specify compliance with recognized international or national regulations regarding formaldehyde emission, fire resistance, or other relevant quality measures.

What are some common applications of high-density fiberboard (HDF) in construction?

In construction, HDF is commonly used as a subflooring or underlayment material. It can also be utilized for roofing, siding, and in various building applications where a durable and moisture-resistant material is required.

How does surface finishing affect my choice of high-density fiberboard?

Surface finishing such as melamine or UV coating can enhance the HDF's resistance to wear and tear, as well as its aesthetic appeal. The choice of surface finishing should align with the expected longevity and appearance of the board.

What are the color options available for high-density fiberboards?

High-density fiberboards come in various color options, including plain, wood grain, and other finishes. The choice of color can complement or match other design elements in your project.

What are the considerations for using high-density fiberboards in furniture manufacturing?

For furniture manufacturing, it is important to consider the durability of the board, its resistance to wear, ease of finishing, and whether it meets industry standards for environmental friendliness. Customizability options may also be relevant.

How do I choose between different door materials like MDF and plywood?

The choice between MDF and plywood depends on the specific requirements of your project. MDF is generally more uniform and easier to paint or veneer, whereas plywood offers a more natural and strong solution with its layered structure.

Can high-density fiberboard be used for soundproofing purposes?

While high-density fiberboards themselves do not provide soundproofing qualities, combining them with other materials in construction can contribute to sound insulation. Thicker boards or specialized acoustic formulas may be used for soundproofing applications.

What is the typical lifespan of high-density fiberboards in construction applications?

The lifespan of high-density fiberboards in construction depends on the quality of the material used, the environmental conditions it's exposed to, and how well it's maintained. Generally, well-kept high-density fiberboards can last several decades with proper care.

Are there eco-friendly options available among high-density fiberboards?

Yes, there are eco-friendly options available that use materials with lower formaldehyde emissions or are made from sustainably managed sources. Suppliers may also offer products with recycled content or from certified sustainable forests.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4