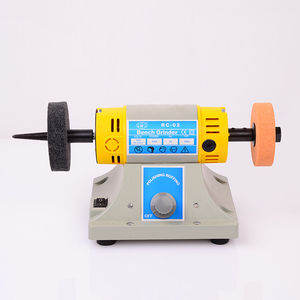

When selecting the right gem cutting and polishing equipment on Alibaba.com, it's essential to consider the variety and features of the tools available. Among the offerings, you'll find specialized saws and polishing machines designed for jewelry making. These tools are tailored for precision and ease of use, ensuring that every cut and polish contributes to the creation of beautiful jewelry pieces.

For those working with porcelain, turbo diamond saw blade discs come in various sizes, from 105mm to 250mm, and are engineered for hot press cutting. These blades are an example of the specific equipment available for intricate cutting tasks, ensuring clean cuts across different materials.

Professionals in the gemstone industry might look for high-grade wet cutting saw blades, which are suitable for cutting harder materials like stone. With sizes up to 350mm, these blades are designed for both precision and durability. Additionally, the marketplace includes diamond cutting discs and saw blades for marble and granite, indicating a range of tools for different stone types and cutting requirements.

For detailed and delicate work, such as setting gemstones or creating intricate jewelry designs, tools like bearing cutting burs and multifunction cutting machines are available. These tools offer precision for detailed craftsmanship. Moreover, for those seeking to cut specific types of gems, cold-pressed diamond gem saw blades are available for materials like agate and jade.

Lastly, Alibaba.com caters to the needs of those requiring advanced equipment, such as digital gemstone faceting machines, which allow for precise control over the cutting process, enabling the creation of perfectly faceted gems. The selection of equipment on the platform is diverse, catering to various aspects of gem cutting and polishing, from rough cuts to fine detailing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4