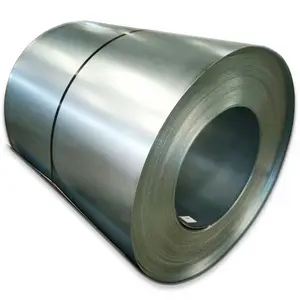

Galvanized steel coils are sheets of carbon steel coated on both sides with zinc. They are used for myriad applications, mostly in construction, because they are both durable and low maintenance.

How Galvanized Coils Are Made

There are two main processes for producing galvanized steel coils. The first method is known as electrogalvanizing. This is where zinc is applied to the GI steel coil through an electrolytic treatment. The process causes the layer of zinc to firmly adhere to the base metal through the bonding layer. Hot-dipped galvanized steel coils, on the other hand, are processed by passing the steel through a molten zinc bath.

Galvanization is an economical and effective process that protects the naked steel from corrosive elements. The zinc acts as a barrier between the PPGI coils and the environment. It also will sacrifice itself to protect the prepainted galvanized steel coils from decomposition.

Benefits of Galvanized Steel Coils

Galvanized coils have many benefits, starting with cost. It is lower in cost than many other protective coatings for steel. It is low maintenance, which means it has a low long-term cost as well. The life expectancy of galvanized steel coils used on a typical structure in a rural setting is in excess of 50 years, and 20 to 25 years in an urban environment. The galvanized coating offers protection even to sharp corners and inaccessible areas.

Practical Applications of Galvanized Coil Stock

The primary use of PPGI steel coils by builders is in roofing. Used in this application, prepainted galvalume steel coils acts as a protective barrier for the ridges and valleys in roofing systems. The galvanized steel coil is flattened onto the roof and then bent into the crease at the top to protect the roof panels' joints from exposure to the environment. This also creates a way for the rain and snow to run off the roof. The pre-painted galvanized steel sheet is sealed to prevent water from seeping underneath.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4