Understanding the Utility of Flexible Foam Tubing for Insulation Solutions

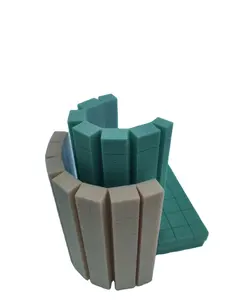

Flexible foam tubing serves as a versatile and effective method for maintaining temperature and sound control in various environments. Crafted from materials like polyethylene, PVC, and rubber, these tubes bring a host of benefits such as high thermal resistance, moisture resilience, and sound absorption capabilities. They find widespread application in construction, HVAC systems, and industrial settings where insulating pipes and ductwork is essential.

The fundamental concept behind flexible foam tubing is straightforward: it acts as a shield to prevent heat loss or gain, thus aiding in regulating internal temperatures and cutting down on energy expenses. Its pliability enables a snug fit around pipes and fixtures, while its resistance to water and chemicals safeguards contents from environmental harm. Apart from insulation, the tubing also provides cushioning and structural reinforcement.

Designed to cater to a diverse user base ranging from contractors and engineers engaged in construction projects to manufacturers in need of industrial equipment insulation, the efficacy of flexible foam tubing lies in its structure. Whether open or closed-cell foam, with air or gases trapped within, this design not only ensures excellent insulation but also renders the material lightweight and easy to install.

Variants of Flexible Foam Tubing for Insulation Solutions

The market offers an array of flexible foam tubing types, each tailored to specific insulation requirements:

-

Polyethylene (PE) Tubing: Among the most prevalent types for general insulation purposes due to its cost-effectiveness and varied densities. Commonly used in residential and commercial buildings for insulating pipes, air ducts, and as protective padding in sports equipment.

-

Polyvinyl Chloride (PVC) Tubing: Renowned for durability and resistance to diverse chemicals, PVC-based flexible foam tubes are extensively employed in industrial setups for insulating electrical cables and as core insulation in composite materials.

-

Rubber Foam Tubing: Rubber-based foams offer exceptional flexibility and high-impact absorption, making them ideal for heavy-duty applications like shock absorption in sports equipment and thermal insulation in appliances.

-

Polyurethane (PU) Tubing: PU foam tubes boast good thermal insulation properties and sound absorption capabilities. Commonly found in construction for pipe lagging, wall insulation, and noise reduction in appliances.

-

Cross-Linked Polyethylene (PEX) Tubing: Recognized for its eco-friendly composition, PEX foam tubing contains cross-linked polyethylene, enhancing its heat resistance and shape retention over time.

Selecting the Right Flexible Foam Tubing for Insulation Solutions

Choosing suitable flexible foam tubing for insulation demands consideration of various factors aligning with project-specific needs. Material composition is of utmost importance; options such as NBR, PVC, EVA, rubber, PE, and silicone offer distinct insulation and resistance properties tailored to specific applications. Businesses should also assess the operating temperatures and environmental conditions the foam will encounter—certain types may degrade under high temperatures or exposure to specific chemicals.

Another critical aspect is determining the required thickness of the tubing. While thicker walls generally offer superior insulation, they may impact the foam's flexibility and compressibility. The chosen foam type should also accommodate any necessary processing services like cutting or welding to be conducted on-site.

When making purchases on Alibaba.com, buyers should seek suppliers providing post-sale services such as onsite installation assistance or product warranties, ensuring peace of mind during project completion.

Furthermore, as Alibaba.com caters to a global market, considering the proximity of local service locations when selecting a supplier is vital. Proximity can influence shipping costs and lead times, making it more practical for businesses to source from nearby suppliers.

Exploring the Realm of Flexible Foam Tubing for Insulation Solutions on Alibaba.com

Alibaba.com serves as a leading global marketplace connecting businesses with a myriad of suppliers offering a wide selection of flexible foam tubing options. Prioritizing versatility and procurement convenience, Alibaba.com ensures a seamless sourcing experience regardless of industry or project requirements—be it HVAC system insulation solutions or protective coverings for electronics.

The platform's advanced filtering tools empower buyers to pinpoint specific needs based on material types like NBR or PVC, features such as eco-friendliness or waterproofing abilities, and industry-specific requisites like HVAC system insulation or medical device enclosures. Moreover, Alibaba.com's commitment to facilitating international trade is underscored by services like Trade Assurance, safeguarding transactions until delivery confirmation.

For businesses aiming to streamline their supply chain or efficiently source materials while upholding quality standards, Alibaba.com's extensive range of flexible foam tubing stands as an invaluable asset. By bridging buyers with suppliers across different countries, Alibaba.com plays a pivotal role in bolstering small and medium-sized enterprises in their global growth pursuits.

Frequently Asked Questions on Flexible Foam Tubing for Insulation Solutions

What are the primary advantages of utilizing flexible foam tubing for insulation?

Flexible foam tubing offers exceptional thermal insulation properties, aiding in reducing energy costs by maintaining consistent temperatures in pipes and equipment. Its resistance to moisture and various chemicals ensures longevity and reliability across diverse environments.

How can I ascertain the correct size of flexible foam tubing for my project?

The appropriate size of tubing for your project is determined by the required inner diameter and wall thickness to suit your specific application. Measuring the installation area's dimensions is crucial to ensure a proper fit.

Can flexible foam tubing be employed for both hot and cold water applications?

Absolutely, flexible foam tubing is suitable for both hot and cold water applications owing to its thermal properties that accommodate a range of fluid temperatures within operational limits.

Are there different types of flexible foam tubing tailored to various applications?

Indeed, a variety of flexible foam tubing types exist, including NBR, PVC, EPDM, EVA, and polyethylene foam, each possessing specific properties suitable for diverse applications.

What considerations are pivotal when choosing between NBR and PVC flexible foam tubing?

When deciding between NBR and PVC flexible foam tubing, factors to contemplate include application compatibility with transported fluids, required temperature resistance, flexibility needs, and specific attributes such as UV stability or chemical resistance.

How does the wall thickness of a flexible foam tube impact its performance?

The wall thickness of a flexible foam tube influences its insulation effectiveness. Thicker walls offer enhanced thermal insulation and durability, particularly beneficial for applications involving high pressures or extreme temperatures.

Is it feasible to customize flexible foam tubing to suit unique project requirements?

Many suppliers provide customized options for flexible foam tubing, offering different sizes, shapes, and additional features to meet specific project demands.

What are the environmental advantages of using eco-friendly flexible foam tubing?

Eco-friendly flexible foam tubing, derived from materials with reduced environmental impact, can be recyclable or biodegradable based on the specific foam type employed.

How does surface handling influence the choice of flexible foam tubing?

Surface handling methods like screen printing or hot stamping can enhance the durability and appearance of flexible foam tubing. Selection of these finishing processes should align with the tubing's intended use and aesthetic preferences.

Is it possible to request a sample before making a bulk purchase of flexible foam tubing?

Many suppliers on Alibaba.com offer the option to procure a sample before committing to a larger purchase, enabling assessment of product quality and suitability for the intended application.

What are some common applications for flexible foam tubing?

Typical applications of flexible foam tubing encompass thermal insulation for pipes, air conditioning systems, refrigeration equipment, and packaging to safeguard fragile items during transit.

How can I ensure that the flexible foam tubing I buy adheres to industry standards?

When procuring flexible foam tubing, seek products conforming to industry standards like ASTM, ISO, or other pertinent certifications to ensure compliance with regulatory requisites.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4