Top categories

Leather Products

Yarn

Fiber

Thread

Textile Processing

Textile Accessories

Other Textiles & Leather Products

Leather

Fur

Down & Feather

Fabric

About products and suppliers

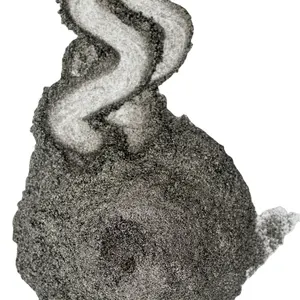

Flocking powder is a material consisting of finely cut fibers that create a fuzzy or velvety texture on various surfaces, making it popular in do-it-yourself (DIY) projects and crafts. The monofilament fibers usually come from nylon, rayon, or other synthetic fibers. A user applies flocking powder to an adhesive-coated surface, such as fabric, paper, or other materials. Excess powder is brushed away when the surface has dried.

Applications of flocking powder

With its distinctive texture and appearance, flocking powder is often used in crafting, decorating, model-building and educational applications. Using flocking powder for crafts adds a tactile and unique finish to projects. Model builders rely on flocking powder to create landscapes in miniature form, using the powder to replicate grass, moss, or animal fur in architectural models and dioramas. Christmas tree flocking spray is widely used to enhance holiday trees, while snow flocking powder adds a snowy element to decorations, ornaments, and wreaths. Flocking powder is useful in developing tactile learning materials for children, which promotes engagement and exploration. In the production of medical equipment and the automotive and aerospace industries, flocking powder may be used to reduce glare, create a comfortable touch surface, and improve the feel of controls.

Features of flocking powder

Flocking powder is well-known for imparting a soft and velvety texture to surfaces. From fine to coarse, the textures created are based on the size of the fibers in the powder. Flocking powder is used on various surfaces, including fabric, plastic, and wood, and adheres well when an appropriate adhesive is applied. Self-adhesive flocking powder makes the process more convenient for users. To achieve unique results, flocking powder can be easily combined with other crafting materials, such as paint, glitter, and decorations. Aside from white flocking powder, flocking powder is available in various colors, allowing users to select the shade they need for their projects. The range of colors expands the possibilities for customization and design.

Maintenance of flocking powder

Flocking powder requires gentle care to maintain its soft texture and appearance. Regular cleaning is essential, using light brushing or vacuuming to remove dust without causing damage. Harsh abrasives and excessive rubbing must be avoided to preserve the delicate flocking fibers. Industrial applications of flocking powder, such as automotive interiors or electronics, require routine inspections to address wear or damage promptly. Minimizing exposure to sunlight and weather can prevent fading. Flocking powder needs to be stored in a dry, cool environment to prevent degradation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4