Introduction to EPE Foam Sheet Production

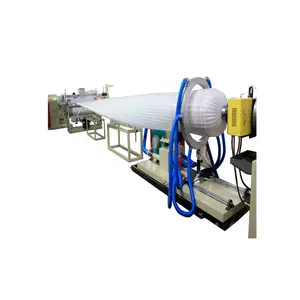

The realm of plastic manufacturing has been revolutionized with the advent of the epe foam sheet making machine. This equipment is pivotal in the production of expanded polyethylene (EPE) foam sheets, a material known for its versatility and wide range of applications. EPE foam is characterized by its lightweight, shock-absorbing properties, making it an ideal choice for packaging, insulation, and cushioning products.

Types of EPE Foam Sheet Machines

When it comes to the epe foam making machine, prospective buyers will encounter primarily two variants: single screw and double screw extruders. The double screw models are lauded for their efficiency, as they harness the power of two screws to amplify production capacity. Conversely, single screw extruders are more cost-effective and perfectly suited for operations with lesser volume demands. Each type serves the end goal of transforming EPE pellets into malleable foam sheets.

Applications and Features

The application of epe foam sheet making machines extends beyond mere packaging solutions. These machines are instrumental in producing materials for construction insulation, sports equipment, and even automotive parts. The versatility of the machine allows for a broad spectrum of plastic shapes, from intricate profiles to expansive sheets. Features of these machines often include customizable sheet widths and thicknesses, ensuring adaptability to specific production requirements.

Materials and Advantages

EPE foam making machines are designed to work with EPE material, known for its resilience and environmental resistance. The end product, EPE foam, boasts advantages such as thermal insulation, non-toxicity, and water resistance. The machinery itself is constructed to withstand the rigors of industrial environments, ensuring longevity and consistent performance.

Choosing the Right Machine

Selecting the appropriate epe foam sheet making machine hinges on understanding the specific needs of a business. Factors such as production volume, space availability, and the desired properties of the final product play a crucial role. While double screw extruders may offer higher output, single screw machines can be more than sufficient for certain operations, balancing cost with capability.

Conclusion

In conclusion, the epe foam sheet making machine stands as a cornerstone in the plastic manufacturing industry, offering a blend of efficiency and versatility. For businesses looking to procure such machinery, Alibaba.com serves as a gateway to a wide array of options, catering to diverse production demands without advocating for any specific brand or service.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4