Introduction to Eccentric Press Machines

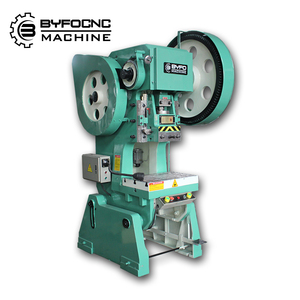

An eccentric press is a type of machine that utilizes a mechanical action to shape or cut materials with precision. This category encompasses a variety of machines designed for specific industrial tasks, ranging from metal forming to cutting operations. The eccentric press operates on the principle of a rotating offset shaft, which converts rotary motion into a linear pressing motion, making it a vital component in manufacturing and metalworking industries.

Types of Eccentric Press Machines

The eccentric press machine category is diverse, with each type tailored to meet different industrial requirements. Hydraulic and pneumatic presses offer power and efficiency for high-volume tasks, while manual punches cater to more straightforward, less intensive operations. For operations demanding high precision, CNC punching units are available, which allow for programming of complex tasks and are suitable for continuous mass production. Servo-driven models are also present in the market, ensuring top-notch accuracy for specialized sectors.

Applications and Features

Eccentric presses are integral in shaping and processing sheet materials. Their applications span across various sectors, including automotive, aerospace, and electronics, where they perform tasks such as embossing, punching, and coining. Features of these machines vary, with some offering advanced automation capabilities, adjustable stroke lengths, and energy efficiency. The adaptability of the eccentric press to different materials and complex tasks makes it a versatile tool in any production line.

Materials and Advantages

Constructed to handle a range of materials, from metals to plastics, the eccentric press machine is designed for durability and resilience. The advantages of using an eccentric press include enhanced production speed, uniform product quality, and the ability to perform multiple operations with a single setup. These machines are crafted to withstand the rigors of industrial environments, ensuring longevity and consistent performance.

Selecting the Right Eccentric Press

Selecting the appropriate eccentric press involves considering factors such as material type, production volume, and the specific application. The platform categorizes these machines by type and management classification, aiding in the search for the right fit for a business's unique needs. Whether the requirement is for a portable unit for field repairs or a robust machine for continuous production, the platform facilitates the discovery of a suitable eccentric press machine.

Conclusion

In conclusion, the eccentric press is a fundamental piece of equipment in the manufacturing sector, known for its precision and versatility. The platform's extensive catalogue of eccentric presses, devoid of any specific brand promotion, ensures that businesses can find the machinery that aligns with their operational requirements and enhances their production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4