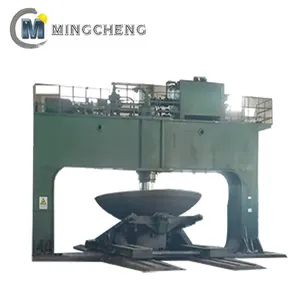

Dished End Flanging Machine Overview

The dished end flanging machine is a specialized piece of equipment designed for shaping metal ends into a dished form. This machinery is crucial in various industries, including pressure vessel manufacturing and tank construction. Its primary function is to produce ends that are essential components in creating cylindrical or spherical vessels.

Types and Applications

There are several types of dished end flanging machines, each serving specific applications. Hydraulic and mechanical flanging machines are common, catering to different production volumes and precision requirements. These machines are widely used in industrial sectors such as petrochemical, pharmaceutical, and food processing, where they play a vital role in the production of storage tanks and boilers.

Technical Features

A dished end flanging machine is equipped with features that ensure efficiency and accuracy. The equipment typically includes a robust frame, precision flanging rolls, and advanced controls for the flanging process. These features contribute to the machine's ability to handle various materials and thicknesses, ensuring versatility across multiple applications.

Material Handling and Advantages

The construction of a dished end flanging machine allows it to work with a range of materials, from carbon steel to stainless steel and even some alloys. The advantage of using such machinery lies in its ability to produce consistent and uniform dished ends, which are critical for the integrity of pressure vessels and tanks.

Choosing the Right Machine

Selecting the appropriate dished end flanging machine involves considering factors such as material type, end diameter, and the specific industry application. Alibaba.com hosts a comprehensive catalog where buyers can compare different models and features to find the machine that fits their project requirements.

Operational Excellence

Operational excellence in the use of a dished end flanging machine is paramount. Prospective buyers should focus on machines that offer precision control, ease of operation, and the ability to integrate with other manufacturing processes. While Alibaba.com facilitates the connection between buyers and suppliers, it is essential to evaluate the machinery based on these operational parameters.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4