Introduction to Dieless Cutting Machines

Dieless cutting machines represent a significant advancement in the field of material processing, offering a versatile solution for creating precise cuts without the need for custom-designed dies. These machines are particularly beneficial for industries that require rapid changes in design and production runs, such as paper goods manufacturing.

Types and Applications

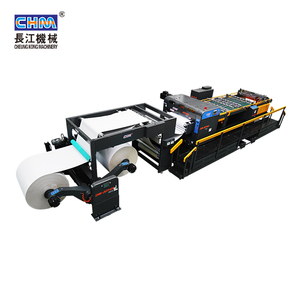

The variety of dieless cutting systems caters to different scales of production needs. From compact models suitable for small-scale operations to robust units designed for high-volume output, these machines serve an array of applications. Industries ranging from hospitality to large-scale paper processing facilities utilize dieless cutting technology for products like toilet papers, napkins, and other paper items.

Operational Features

A typical dieless paper cutting machine integrates multiple functionalities, including embossing, slitting, and folding. The embossing process can be performed using diverse patterns, thanks to the adaptable steel-to-steel or steel-to-rubber systems. Moreover, advanced dieless cutting equipment often comes with photoelectric sensors to monitor operations and maintain efficiency.

Technical Specifications

Dieless cutting machines vary in size and power consumption, with smaller units starting at a weight of approximately 1,000kgs and a power usage of 3kw or more. These machines are capable of producing 70 to 80 pieces per minute. Larger variants, suitable for greater production demands, can weigh over 3,000kgs and achieve outputs of around 3 tons per day. The operational mechanisms may include gear or chain driving systems, with many models boasting full automation and PLC control panels for streamlined operation.

Automation and Safety

The integration of automation in dieless cutting technology enhances production efficiency and safety. Automatic oil lubrication systems ensure consistent machine performance, while safety alarms are triggered by the photoelectric technology in case of paper shortages or operational issues. This level of automation ensures that the dieless cutting process is both reliable and user-friendly.

Choosing the Right Machine

Selecting the appropriate dieless cutting equipment depends on the specific requirements of the production environment. Factors such as production capacity, space availability, and the desired level of automation play a crucial role in determining the most suitable machine. Prospective buyers can explore a wide range of options on Alibaba.com to find the equipment that aligns with their operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4