Understanding the Cylindrical Grinder

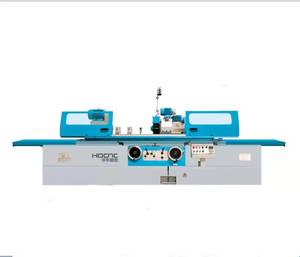

A cylindrical grinder is a pivotal machine tool for precision grinding, shaping the external surface of an object. The object may have a central axis of rotation, making it ideal for the precise and fine machining of cylindrical and tapered surfaces. This category encompasses various models, including the universal cylindrical grinder, which is designed for a range of cylindrical grinding tasks, and the CNC cylindrical grinding machine, which offers enhanced control and precision in complex grinding operations.

Types and Applications of Cylindrical Grinding Machines

The cylindrical grinding machine is not a one-size-fits-all solution. Specific types, such as the ID OD grinder and the universal grinder machine, cater to internal and external surfaces, respectively. These machines are employed in numerous industries, from manufacturing plants to machinery repair shops. The OD grinder, for instance, is essential for finishing the outer diameters of components, while an internal grinder machine is more suited for interior surface precision.

Features and Materials

Cylindrical grinders are constructed from durable materials like stainless steel, zinc alloy, or aluminum alloy, ensuring longevity and consistent performance. The robust nature of a studer grinder—a brand synonymous with precision—highlights the importance of material quality in achieving fine finishes and maintaining dimensional accuracy over prolonged use.

Advantages of Modern Cylindrical Grinders

Modern advancements have led to the development of the CNC cylindrical grinder, which brings forth advantages in precision and efficiency. These computer-controlled machines reduce human error and enhance productivity by automating complex grinding tasks. The precision offered by these machines is crucial for applications requiring high levels of accuracy and surface integrity.

Choosing the Right Cylindrical Grinding Machine

Selecting the appropriate machine depends on various factors, including the nature of the grinding operation and the size of the components. For businesses looking to acquire a grinding machine, options range from brand new state-of-the-art equipment to used cylindrical grinders and second hand cylindrical grinding machines, providing cost-effective solutions without compromising on functionality.

Conclusion

The cylindrical grinder remains an indispensable tool in the realm of metalworking. With a spectrum of machines available, from the manually operated universal cylindrical grinding machine to sophisticated CNC variants, businesses can select the ideal model that aligns with their operational needs and production demands. While Alibaba.com serves as a marketplace to connect buyers with a diverse array of suppliers, it is essential to consider the specific requirements and capabilities of the cylindrical grinding equipment to ensure the right investment is made.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4