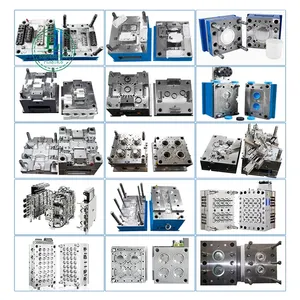

Exploring Custom Plastic Injection Mold Solutions

The realm of custom plastic injection mold manufacturing is a cornerstone in the production of diverse plastic parts. This process is pivotal for businesses seeking tailored solutions for their plastic component needs. Injection molds are crafted with precision to ensure that each product meets specific design requirements, providing a versatile approach to plastic manufacturing.

Types and Applications of Injection Molds

Custom injection molding services cater to a broad spectrum of industries, from automotive to consumer goods. The versatility of custom plastic molding allows for the creation of intricate components for small gadgets as well as larger, more complex parts. Each mold is designed to accommodate the unique geometry and specifications of the intended product, ensuring functionality and aesthetic appeal.

Material Selection in Mold Making

Material choice is a critical decision in the creation of custom molds for plastic. Options range from various grades of steel to aluminum, each offering distinct advantages in terms of durability and thermal conductivity. The selection is influenced by the projected production volume, the plastic material being molded, and the complexity of the mold design.

Features and Advantages of Custom Molds

Investing in a custom plastic injection moulding solution can lead to significant cost efficiencies in the long term. Standardizing elements such as lift bars and clamp slots can streamline the manufacturing process. Moreover, the adaptability of custom molded plastics allows for a high degree of customization, ensuring that the end product aligns perfectly with the client's requirements.

Ensuring Quality and Precision

Quality is paramount in custom injection molding. Molders near you, such as envirotech custom injection molders and quality custom molding llc, focus on creating test samples to validate the mold's performance. This iterative process continues until the mold produces parts that meet the client's standards, ensuring precision in the final output.

Cost Considerations in Custom Molding

While discussing custom injection molding cost, it's important to consider the value it brings to the production cycle. Custom molds may represent an initial investment, but they can reduce costs over time by enhancing production efficiency and reducing waste. Clients can consult with a custom plastic molding company to understand the cost-benefit analysis of their project.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4