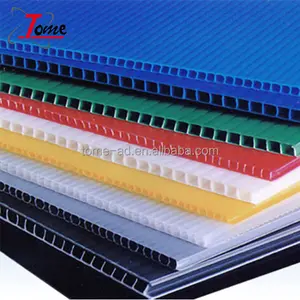

Corrugated plastic sheets, also known as corrugated plastic or coroplast, are a versatile and widely used material known for their unique combination of lightweight yet durable properties. Corrugated plastic sheet usually comprises what appear to be three layers - two flat sheets with a ribbed center layer. In fact, they are really two layers, often referred to as twin-wall plastic.

Advantages of corrugated plastic sheets

Corrugated plastic sheets offer a range of distinct advantages. They have gained popularity in crafting homemade cages for small animals like guinea pigs, hedgehogs, and rabbits, as well as in the remote-controlled aircraft industry for SPAD model aircraft. The material's lightweight nature makes it easy to transport, store, lift, assemble, and set up with minimal effort. Furthermore, corrugated plastic is highly affordable to produce and purchase, making replacements cost-effective, and it can be procured within budget constraints. Its durability allows it to withstand diverse environmental conditions, ensuring a long-lasting performance. Corrugated plastic, made from polypropylene, is non-toxic to both humans and animals, without harmful chemicals like BPA, and remains stable under extreme temperature variations. Additionally, its recyclable nature enables eco-friendly disposal options, although it is non-biodegradable.

Materials of corrugated plastic sheets

Typically, either polypropylene, polyethylene, or polycarbonate is used to make corrugated plastic panels. These thermoplastics are the ideal option for this purpose since they are strong and simple to manufacture by extrusion. A fluted polypropylene sheet is more resistant to chemical corrosion due to the pH's neutrality. If needed, it can also receive chemicals that make it fire- and UV-resistant. Corrugated polycarbonate sheets can have drawbacks, including poor impact resistance and high brittleness, but they can also function effectively in applications where these drawbacks aren't a big deal. In addition to these two components, PVC and PETG can also be used to make corrugated plastic.

Common uses of corrugated plastic sheets

Corrugated plastic sheets find versatile applications across various industries. In the building sector, corrugated plastic roof panels' exceptional strength and lightweight properties make them suitable for roofing and shutters, and their corrugated design provides effective insulation with air trapped within the core. Temporary shelters benefit from its lightweight, affordable nature, making it an ideal choice for quick setup and tear down in disaster-stricken areas, offering weatherproof protection. In the packaging industry, its flexibility and impact resistance are valuable for creating components that safeguard items during shipping and display. The availability of various colors and ease of printing make corrugated plastic an excellent choice for signage, including temporary yard signs, billboards, and corrugated plastic sign boards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4