A furnace is a laboratory tool or instrument that is shaped like a furnace that produces heat. The heat is then transferred to the material to be smelted. There are two types of furnaces in general which are coreless (high frequency) and core (low frequency, around 60 Hz).

Different types of copper melting furnaces and their working principles

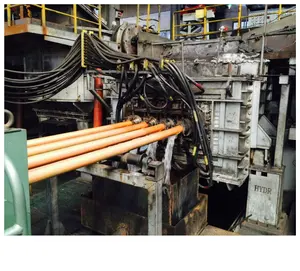

Copper smelting furnace uses three-phase alternating current. The heat energy is provided by an electric arc between the carbon electrode and the molten steel. This smelting furnace is a heat-producing furnace with an operating temperature above the melting point of the material to be processed. Melting furnace for copper has a heat generation system where heat is generated from electrical energy flowing through an electrode or arc, which is called "direct arc" and "indirect arc" as a conductor. Homemade crucibles for copper and copper melting forge are typically used in the small-scale foundry industry, which is used in processing non-ferrous metals. They can also adjust the chemical composition on a small melting scale. Electric copper melting furnaces and induction furnaces for copper melting can be used for superheating (heating the molten metal above its normal liquid temperature to improve flowability), temperature containment (keeping the molten metal at a constant temperature for a long time for the die-casting process), and duplexing/parallel furnace (uses two furnaces as in the operation of melting metal in one furnace and transferring it to another furnace). The heating process is assisted using various types of fuel. Homemade smelter for copper can be applied to both ferrous and non-ferrous metal which is often used as a smelting furnace in producing cast iron with certain functionality.

Main components of a copper melting furnace and their features

Chimney (stack) serves as a disposal site for combustion gases. The material used for the chimney structure is usually made of carbon steel plate. A soot blower removes soot and other impurities that stick to the pipe surface, which can inhibit the heat transfer process. The soot is then expelled through the chimney along with the combustion gases. Tubes functions as a place for the flow of fluid to be heated. The burners in the copper melting machine have the function of burning fuel, which consists of a mixture of gas and air. Gas and air must mix well at a certain point so that the combustion process can work out properly.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4