Introduction to Composite Sandwich Panels

Composite sandwich panels are advanced materials widely utilized in various industries for their exceptional strength-to-weight ratio and insulation properties. These panels consist of two outer skins surrounding an inner core material, which can vary based on the application requirements. The versatility of composite sandwich panels makes them suitable for a range of applications, from aerospace to construction.

Core Materials and Types

The core of a composite sandwich panel is pivotal in defining its properties. Common core materials include EPS (Expanded Polystyrene), PIR (Polyisocyanurate), and mineral wool, each offering distinct advantages. EPS cores provide a balance between fire resistance and insulation, while PIR cores are favored in extreme temperature environments for their superior insulative qualities. Mineral wool cores excel in fire insulation, making them ideal for use in regions prone to wildfires. Other specialized cores like carbon fiber are also available, catering to high-strength, lightweight requirements.

Applications and Features

Insulated sandwich panels are employed in a multitude of settings. Their lightweight nature coupled with robustness makes them perfect for architectural projects, including facades and roofing systems. The insulation features of foam sandwich panels are particularly beneficial in residential and commercial buildings, contributing to energy efficiency and cost savings. In industrial sectors, fiberglass sandwich panels are often used for their durability and resistance to environmental factors.

Environmental Advantages

The environmental impact of construction materials is a growing concern, and composite sandwich panels offer a sustainable option. Their insulative properties can significantly reduce energy consumption in buildings, thereby lowering carbon footprints. Additionally, the lightweight nature of aluminum sandwich panels reduces transportation emissions and the overall energy required for installation.

Material Composition and Advantages

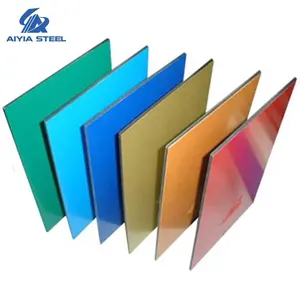

Composite sandwich panels are designed with two aluminum sheets encapsulating the core material. This design not only enhances the panel's durability but also provides excellent thermal insulation. The aluminum surface can be treated or coated to offer additional benefits such as corrosion resistance or aesthetic appeal. The ease of installation and cost-effectiveness of these panels make them a competitive alternative to traditional masonry in construction.

Choosing the Right Panel

Selecting the appropriate composite sandwich panel for a specific application is crucial. Factors such as thermal requirements, fire resistance, structural strength, and environmental conditions must be considered. Alibaba.com hosts a diverse range of options to cater to these varied needs, ensuring that buyers can find the right fit for their project specifications without the hassle of navigating through countless suppliers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4