Understanding CO2 Welding Wire Spools

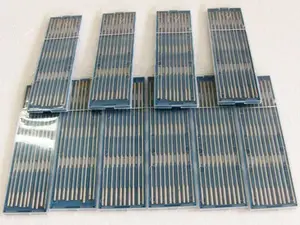

CO2 welding wire spools are integral components in the welding industry, serving as the consumable electrode in gas metal arc welding (GMAW) processes. These spools consist of lengthy, thin metallic rods designed to create a stable, heated arc that facilitates the fusion of metals.

Types of CO2 Welding Wires

Diverse welding projects require specific types of CO2 welding wire spools. The selection typically includes solid GMAW wires, composite GMAW wires, and gas-shielded flux-cored arc welding (FCAW) wires. Solid GMAW wires utilize a shielding gas and are known for their clean operation. Composite GMAW wires, while similar in composition, contain additional metallic elements that enhance their performance. FCAW wires, enriched with deoxidizing and fluxing agents, are recognized for their robust application, despite producing more splatter.

Applications and Features

CO2 welding wire spools are versatile, finding applications across various sectors such as automotive, shipbuilding, and manufacturing. The choice of wire affects the welding operation's speed, tolerance, and strength, with composite GMAW and FCAW wires often providing superior results in these areas. The diameter and type of wire chosen are crucial for the success of the welding process, influencing the weld's integrity and appearance.

Material Composition and Advantages

The material composition of CO2 welding wire spools is tailored to meet the demands of different welding tasks and base metals. The advantages of using the appropriate wire are manifold, including improved weld quality and increased productivity. The correct selection of wire can significantly enhance the welding process, leading to more reliable and durable metal joints.

Selecting the Right CO2 Welding Wire Spool

Choosing the right CO2 welding wire spool involves considering the welding task at hand and the base metals involved. Factors such as the wire's material composition, diameter, and type play a pivotal role in achieving a successful weld. While the selection process may seem daunting, it is essential for ensuring a high-quality weld.

Conclusion

CO2 welding wire spools are a critical element in the welding process, with their selection bearing directly on the quality and efficiency of the operation. While Alibaba.com facilitates the connection between buyers and suppliers, it is the responsibility of the buyer to choose the most suitable wire for their specific welding needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4