CNC Wire Forming Machine: An Overview

CNC wire forming machines are pivotal in the fabrication of wire into various shapes and configurations. These machines leverage computer numerical control (CNC) to bend wire with precision, catering to a multitude of industrial applications. From simple hooks to complex 3D structures, the versatility of CNC wire forming technology makes it indispensable in today’s manufacturing landscape.

Types and Applications

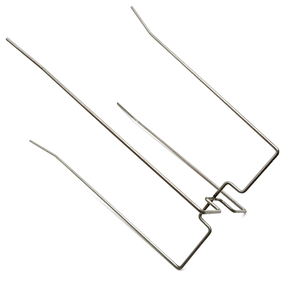

The realm of wire forming machines encompasses a range of types, including the 2D CNC wire bending machine and 3D CNC wire bending machine. The 2D variants are adept at creating flat wire forms, while their 3D counterparts can manipulate wire into three-dimensional shapes. These machines serve various sectors, including automotive, construction, and consumer goods, reflecting their adaptability in producing components like springs, hooks, and intricate wire parts.

Features and Materials

A CNC wire bender is engineered to handle a spectrum of materials, from stainless steel to aluminum, ensuring compatibility with diverse industry requirements. Key features often include multi-axis bending capabilities, automatic wire feeding systems, and intuitive programming interfaces, which collectively enhance operational efficiency and precision.

Advantages of CNC Wire Forming

The adoption of CNC wire forming systems brings forth several advantages. Efficiency in production is markedly improved due to automation, while the precision of CNC technology minimizes material waste. Additionally, the flexibility of these machines allows for quick changeovers between designs, which is crucial for manufacturers aiming to meet varied client demands.

Choosing the Right Machine

Selecting an appropriate wire forming machine requires careful consideration of the machine’s capabilities and the specific needs of the task at hand. Factors such as wire diameter, bending complexity, and production volume play significant roles. Wire forming machine manufacturers and CNC wire bending services can provide insights into the best equipment for particular applications.

Conclusion

In conclusion, the CNC wire forming machine is a key player in modern manufacturing, with its ability to produce precise wire forms quickly and efficiently. While the market offers various models, including the small CNC wire bending machine for lower-volume needs, each variant presents a solution tailored to the complexities of wire forming tasks. Prospective buyers should engage with reputable manufacturers to find the machine that aligns with their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4