Introduction to Cigarette Processing Machinery

The landscape of industrial manufacturing includes specialized equipment tailored for specific production lines, among which cigarette processing machines play a pivotal role in the tobacco industry. These machines are engineered to handle various stages of cigarette production, from assembly to packaging. The category encompasses a range of machinery designed for different functions within the cigarette manufacturing process.

Types and Applications

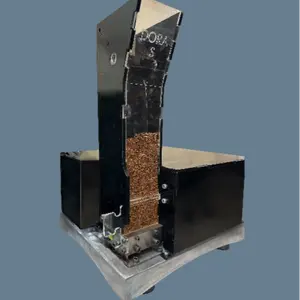

Cigarette manufacturing machinery is diverse, including devices for filling, rolling, and packing. Tobacco processing equipment is also integral, designed to prepare the tobacco before it's encapsulated into cigarettes. These machines are employed in various settings, from large manufacturing plants to smaller specialty shops, demonstrating their versatility across different scales of operation.

Features and Specifications

When selecting a cigarette making machine, it's essential to consider its features and specifications. Machines in this category are often made from durable materials like 304 or 316 stainless steel, ensuring longevity and compliance with industry standards. Advanced models may offer features such as video technical support and online assistance, facilitating ease of use and maintenance.

Materials and Construction

The construction material of a cigarette roller machine is crucial for its durability and hygiene standards. Stainless steel variants, such as 304 and 316, are commonly used for their resistance to corrosion and ease of cleaning, which is essential for consistent production quality and longevity of the machinery.

Advantages of Modern Machinery

Modern cigarette packing machines and processing units are designed to enhance efficiency and precision in cigarette production. They streamline the manufacturing process, reduce waste, and maintain consistent product quality. Additionally, the integration of support services, like technical support, ensures that any operational issues can be promptly addressed, minimizing downtime.

Choosing the Right Machine

Selecting the appropriate cigarette manufacturing equipment requires a thorough understanding of the product's features, the materials used in its construction, and the specific needs of the production line. It's important to consider the type of tobacco, the desired output, and the available support options to ensure seamless integration into existing manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4