Introduction to Cigarette Paper Making Machines

The cigarette paper making machine is an essential component in the tobacco industry, designed to produce high-quality cigarette paper. This specialized equipment streamlines the production process, ensuring a consistent and efficient output of cigarette paper. The machinery varies in size and capability, catering to different scales of production requirements.

Types and Applications

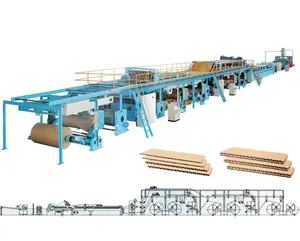

From the smoking paper making machine designed for crafting thinner sheets to the cigarette paper tube making machine focused on creating hollow paper tubes, the diversity in machinery meets various manufacturing demands. These machines are integral in producing not only cigarette paper but also in crafting paper for other smoking products, showcasing their versatility within the industry.

Technical Features and Materials

Cigarette paper machinery is engineered with precision, utilizing advanced technology to handle lightweight materials starting from 20-30g/m2. The machines typically feature a Net Paper Width ranging from 787-900mm and operate at speeds of 20-80m/min. The materials used in the construction of these machines are chosen for their durability and compatibility with the delicate production process of cigarette paper.

Advantages of Modern Machinery

Modern cigarette paper making machines are designed with efficiency in mind, promoting a swift production turnover. They are also constructed to be environmentally friendly, minimizing waste and energy consumption. The design of these machines prioritizes safety, ensuring that operators are safeguarded during the manufacturing process.

Choosing the Right Machine

Selecting the appropriate cigarette paper making machine involves considering the specific needs of a business, such as production volume and the desired features of the end product. Alibaba.com hosts a range of manufacturers and suppliers who can assist buyers in finding the right machinery to fit their operational requirements.

Sustainable Solutions and Efficiency

Investing in the right cigarette paper making equipment can lead to significant returns by enhancing production efficiency and reducing operational costs. Suppliers on Alibaba.com offer machines that are not only effective but also align with sustainable practices, contributing to a greener production cycle.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4