Introduction to Chicken Slaughterhouse Equipment

The chicken slaughterhouse sector is an integral part of the meat processing industry, providing essential equipment designed for the efficient and humane processing of poultry. This category encompasses a variety of machines and tools specifically engineered to optimize the slaughtering process, ensuring that the transition from farm to table is conducted with precision and care.

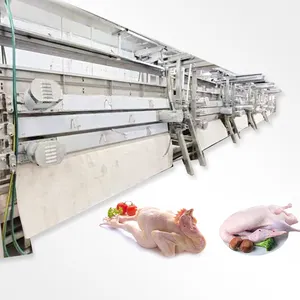

Types of Slaughtering Equipment

Within a chicken slaughterhouse, several types of equipment are utilized, each serving a specific function in the processing line. Pluckers, scalders, evisceration tables, and chilling units are among the common machinery found in these facilities. Each piece of equipment is designed to handle different stages of the slaughtering process, from defeathering to internal organ removal, all the way to cooling the carcasses prior to further processing or packaging.

Features and Applications

Modern poultry processing equipment is characterized by features that enhance efficiency and hygiene. Automation is a key aspect, with many systems designed to minimize human intervention, thus reducing labor costs and increasing throughput. The application of such machinery spans small-scale operations to large commercial processors, each benefiting from advancements in technology that streamline the slaughtering process.

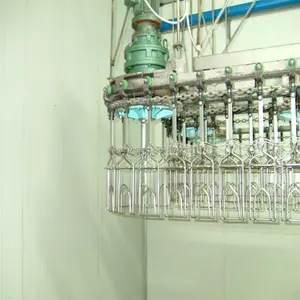

Material and Hygiene Considerations

Materials used in the construction of slaughterhouse equipment are selected for durability and ease of cleaning. Stainless steel is a prevalent choice due to its resistance to corrosion and its non-porous nature, preventing the absorption of bacteria and facilitating a more sterile environment. The importance of hygiene cannot be overstated, as it is critical to prevent meat contamination and to comply with food safety regulations.

Advantages of Upgraded Equipment

Investing in modern chicken processing equipment comes with several advantages. Enhanced speed and efficiency lead to a higher volume of processed poultry, meeting consumer demand more effectively. Additionally, the precision of automated systems can result in a higher yield of meat, reducing waste and potentially increasing profitability. The ease of maintenance and availability of spare parts are also crucial factors that contribute to the uninterrupted operation of a slaughterhouse.

Considerations for Selection

When selecting chicken slaughtering equipment, it is important to consider the capacity to ensure it aligns with operational needs. Furthermore, the availability of spare parts and ease of cleaning should be factored into the decision-making process. While warranties are an important aspect of any capital investment, it is essential to understand the terms offered by suppliers to ensure they align with operational expectations and provide adequate protection for your investment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4