Introduction to Check Weigher Systems

A check weigher is an essential system in the packaging and manufacturing industries, designed to ensure that the weight of a packaged commodity is within specified limits. Any items that are over or under the specified weight are removed, allowing businesses to maintain consistency in product delivery. This introduction delves into the various types of check weighers and their applications across different industries.

Types and Applications of Check Weighers

The versatility of check weighers is evident in their range of types, each suited for specific industry needs. An inline checkweigher is commonly integrated into the production line to weigh products as they move through the line, ensuring a seamless quality control process. For businesses requiring high-precision weighing, a high speed checkweigher is capable of handling large volumes of products at rapid speeds without sacrificing accuracy. In sectors like food processing and pharmaceuticals, a checkweigher metal detector combination is crucial for ensuring product safety and compliance with industry standards.

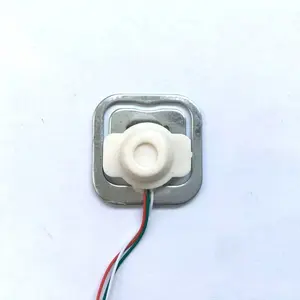

Features and Materials of Check Weigher Machines

Check weigher machines are built with durability and precision in mind, utilizing materials that ensure longevity and hygiene, especially in food-related applications. The construction of these machines often includes stainless steel for its corrosion-resistant properties. Advanced models, such as the dynamic checkweigher, boast features like touch screen controls and real-time data monitoring, which facilitate ease of use and efficiency in production environments.

Advantages of Implementing Check Weigher Systems

Incorporating a check weigher system into your production line can lead to significant improvements in product quality and consistency. These systems help in reducing material waste, ensuring compliance with weight regulations, and enhancing customer satisfaction by delivering products that meet strict weight specifications. An automatic check weigher is particularly beneficial as it automates the quality control process, reducing the need for manual oversight and allowing for continuous operation.

Innovations in Check Weigher Technology

The field of check weighing is continually evolving, with manufacturers like ishida checkweigher and garvens checkweigher at the forefront of innovation. These advancements include the integration of checkweigher conveyors that are adept at handling various product types and sizes, and in motion checkweigher systems that provide accurate weight measurements for products while they are moving.

Choosing the Right Check Weigher Manufacturer

Selecting the right checkweigher manufacturers is crucial for businesses looking to invest in a reliable check weighing solution. It is important to consider the manufacturer's reputation, the technology used, and the range of products they offer to ensure that the chosen system aligns with specific business needs. An online check weigher option allows for remote monitoring and data collection, offering an additional layer of convenience and control.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4