Introduction to Cast Iron Surface Plates

Cast iron surface plates are a foundational tool in industrial and manufacturing settings, known for their durability and precision. These plates serve as a reference base for inspection, tool making, gauging, spotting marking and layout operations. A variety of types are available, each tailored to specific applications and requirements.

Types and Applications

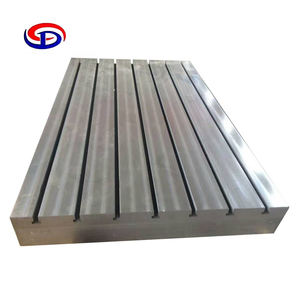

The versatility of cast iron surface plates is reflected in their various forms, such as the cast iron lapping plate, cast iron surface table, and t slot cast iron surface plate. These are utilized across different industries, from machinery repair shops to construction sites, and for purposes ranging from industrial equipment calibration to precision testing.

Features and Materials

Cast iron surface plates are designed with a focus on rigidity and wear resistance, made predominantly from high-grade cast iron. Some variants, like the cast iron floor plate, are reinforced with ribs to maintain accuracy under heavy loads. The surface is often treated or machined to achieve a precise flatness, essential for accurate measurements and equipment alignment.

Advantages of Cast Iron Surface Plates

The inherent properties of cast iron, such as its resistance to deformation and vibration, make iron surface plates a reliable base for critical measurements and complex industrial tasks. Their longevity and ability to maintain dimensional stability over time provide consistent performance, which is crucial for quality control processes.

Selection Considerations

When selecting a cast iron surface plate, factors such as size, grade, and surface finish should be considered. For specialized applications, products like the machinist cast iron lapping plate or cast iron detectable warning surface may be more appropriate. It's important to match the specifications of the plate to the precision requirements of the task at hand.

Pre-Owned Options

For businesses seeking cost-effective solutions, used cast iron surface plates are an option. These plates can still offer the required precision, provided they have been well-maintained and inspected for accuracy and condition.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4