Exploring Carbon Fiber Milling

Carbon fiber milling is a sophisticated process that involves the shaping and finishing of carbon fiber materials. It is a critical component in various industries, offering a unique combination of strength, stiffness, and lightweight properties. This process is essential for creating precision components in aerospace, automotive, and sporting goods, among others.

Types and Applications of Carbon Fiber Milling

The versatility of carbon fiber milling is evident in its applications. End mill for carbon fiber is designed to meet the demands of precision cutting, ensuring clean edges and surfaces. Industries ranging from automotive to aerospace rely on this technology for components that require the highest strength-to-weight ratios. Moreover, CNC milling carbon fiber allows for the creation of complex shapes and designs, which are integral in modern engineering and design solutions.

Features and Materials in Carbon Fiber Milling

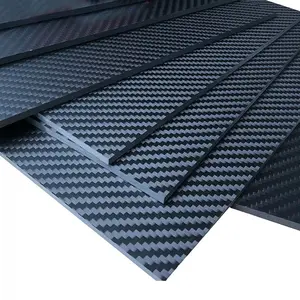

Carbon fiber milling utilizes advanced materials, including laminated polymers and composites. The milling process often involves specialized equipment such as a carbon fiber milling machine, which ensures the integrity and precision of the milled products. Materials used in this process, such as anthracite blocks or rods, are selected for their durability and performance characteristics.

Advantages of Carbon Fiber Milling

The advantages of carbon fiber milling are numerous. Its ability to maintain structural integrity while reducing weight is unparalleled. This is particularly beneficial in applications like creating telescopic poles or milling carbon fiber sheet for industrial use. The process also allows for the customization of products to meet specific industry standards and requirements.

Environmental and Industrial Significance

Carbon fiber milling plays a significant role in environmental applications. Its use in water purification and wastewater treatment projects is a testament to its adaptability and efficiency. In the chemical industry, carbon fiber acts as a catalytic carrier, aiding in the decontamination and decolorization processes. The environmental impact is further seen in its use for air and gas treatment, where it contributes to odor control and enhances reaction rates.

Choosing the Right Carbon Fiber Milling Solutions

Selecting the appropriate carbon fiber milling solutions requires careful consideration of the application and desired outcomes. Whether it is for creating intricate components or for environmental projects, the right choice of carbon fiber milling, such as activated carbon fiber milling, can make a significant difference in the efficiency and effectiveness of the end product.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4