Understanding Cam Follower Bearings

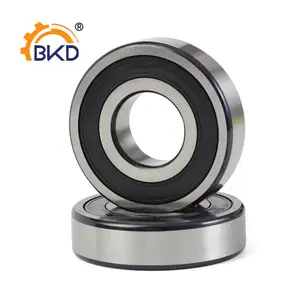

Cam follower bearings are specialized roller bearings designed to follow cam lobe profiles. These components, including cam and follower systems, play a crucial role in various mechanical applications where precision and durability are paramount. The cam follower mechanism is integral to the functionality of machinery, translating rotational motion into linear motion with high efficiency and reliability.

Types and Features of Cam Follower Bearings

There are several types of cam followers, such as eccentric cam followers and roller cam and follower assemblies, each tailored for specific operational needs. Eccentric cam followers allow for adjustment in their position relative to the camshaft, providing a fine-tuning capability for the associated machinery. Roller followers, on the other hand, are known for their ability to carry heavy loads and reduce friction. Among the various models, the cf12 bearing is a common size, known for its versatility and widespread use in industrial applications.

Applications of Cam Follower Bearings

The application of cam follower needle roller bearings extends across numerous industries. They are particularly beneficial in settings that demand precise control, such as in the linear motion guides of heavy-duty machinery. The cam roller bearings are also found in the automotive industry, where they are essential in camshaft mechanisms, contributing to the smooth operation of vehicle engines.

Materials and Advantages

Cam follower bearings are often made from materials like chrome or stainless steel, providing resistance to corrosion and ensuring longevity. Stainless steel variants, such as the iko cam follower, are sought after for their durability and resistance to challenging environments, making them suitable for applications in sectors like marine engineering and food processing.

Selection Considerations for Cam Followers

When selecting a cam follower, it is important to consider the load, the environment of operation, and the required lifespan. For instance, skf cam follower bearings are recognized for their robust construction and can be an excellent choice for heavy-load applications. Additionally, the thk cam follower range is known for its precision manufacturing, which is critical for applications requiring high levels of accuracy.

Maintenance and Efficiency

Maintenance of cam followers is crucial for the longevity and efficiency of the machinery. Bearings such as the ina cam follower are designed for easy maintenance, contributing to reduced machinery downtime and increased productivity. Properly maintained cam followers can significantly enhance the performance and reliability of the equipment they are part of.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4