What is Industrial Bread Manufacturing System

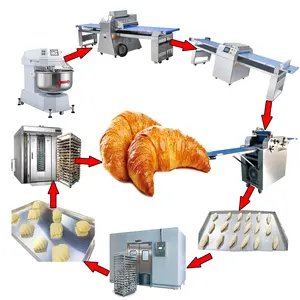

Industrial bread manufacturing systems are sophisticated and specialized equipment designed for the large-scale production of bread and other bakery products. These systems are typically utilized by commercial bakeries, food manufacturing plants, and catering services that require consistent, high-volume output to meet the demands of their customers. The equipment within these systems is engineered to handle various stages of bread production, from mixing and dough preparation to shaping, proofing, baking, and sometimes even packaging.

The key principle behind these systems is automation, which significantly reduces the manual labor involved in the production process. Industrial bread manufacturing systems can vary greatly in complexity, from simple conveyor belts and mixers to advanced robotics and computerized control systems. They are built to ensure efficiency, reliability, and food safety standards while also offering flexibility to accommodate different recipes and production volumes.

These systems often start with a batch mixer or a continuous mixer where the ingredients are combined to form the dough. The dough is then divided, shaped into loaves or other bread forms, and allowed to rest or ferment. Finally, the bread is baked in an industrial oven, and once cooled, it can be sliced, packaged, and distributed. The entire process is carefully orchestrated to maintain the quality and consistency of the final product.

Types of Industrial Bread Manufacturing System

Industrial bread manufacturing systems come in various forms to meet different production needs and preferences:

-

Fully Automatic Systems: These are highly automated with minimal human intervention. They often include components like automatic dough dividers, rounders, and proofers. Fully automatic systems are ideal for large-scale production in bakeries and food manufacturing plants.

-

Semi-automatic Systems: As the name suggests, these systems are partially automated and require more manual input. They often consist of machines like dough rounders and bread slicers. These systems are versatile and can be used for producing a variety of bread types.

-

Specialty Systems: Some industrial bread manufacturing systems are designed for specific types of bread like baguettes or sandwich loaves. These systems are tailored to the particular characteristics of these bread varieties, ensuring consistent results for specialized products.

-

Customized Systems: Businesses can request bespoke industrial bread manufacturing systems that are tailored to their specific requirements. These might include unique configurations of equipment or special features designed for a particular type of bread or production environment.

How to choose Industrial Bread Manufacturing System

Selecting the right industrial bread manufacturing system is a crucial decision for any business involved in the food industry. The choice should be based on the specific needs of the bakery operation as well as the characteristics of the products being produced. Here are some considerations:

-

Capacity and Scale: Assess the volume of bread that needs to be produced, both in terms of daily output and long-term growth plans. Larger-scale operations may benefit from fully automated systems that can handle high-volume production with minimal labor.

-

Space and Layout: Consider the available space within your facility. Some systems may require more room for installation and operation. Also think about the layout of your production line and how the machinery will fit into it.

-

Energy Efficiency: Given the long operating hours of an industrial bread manufacturing system, energy efficiency is important. Look for systems that can reduce energy consumption without compromising on productivity.

-

Maintenance and Durability: Assess the reliability of the system. Machinery should be constructed from durable materials like food-grade stainless steel to ensure longevity and withstand continuous use.

-

Regulatory Compliance: Check that the system meets industry-specific regulations and standards for safety and food quality in your country or region.

By carefully evaluating these factors against your business needs and objectives, you can make an informed decision that will ensure operational efficiency and product integrity in your industrial bread manufacturing process.

About Industrial Bread Manufacturing System on Alibaba.com

For businesses seeking an efficient and reliable industrial bread manufacturing system, Alibaba.com stands out as a premier online marketplace. With an extensive selection of machinery from various suppliers around the globe, Alibaba.com facilitates the procurement process by bringing together all the essential components necessary for commercial-scale bread production. The platform's commitment to connecting buyers with high-quality suppliers ensures that businesses receive machinery that aligns with their specific needs and operational goals.

Alibaba.com's user-friendly interface allows businesses to easily find machinery that meets their requirements—whether they need a compact single-unit system for small-scale operations or a comprehensive solution comprising multiple units for large bakeries. Moreover, with services like Trade Assurance, buyers can engage in transactions with confidence knowing that their payments are protected until delivery is completed.

Businesses looking to expand their bread offerings will find Alibaba.com's global reach particularly valuable. The platform allows access to a wide variety of systems that can accommodate different types of bread production processes—be it standard bulk manufacturing or specialized systems for artisanal or frozen bakery products. With Alibaba.com's support for local languages and mobile-friendly features, sourcing industrial bread making equipment becomes a streamlined process no matter where you are or what your production needs may be.

Common FAQs for Industrial Bread Manufacturing System

What is an Industrial Bread Manufacturing System?

An Industrial Bread Manufacturing System is a comprehensive system designed to automate the process of producing bread, encompassing tasks from dough mixing to baking and slicing.

How do these systems ensure consistency in the bread-making process?

These systems use precision automation and control technologies to ensure that each stage of the bread-making process is carried out consistently, resulting in products that meet the desired quality and specifications.

What types of bread can be produced using these systems?

These systems are versatile and can produce a variety of bread types such as white, whole wheat, multi-grain, rye, and artisanal breads.

What factors should be considered when selecting an Industrial Bread Manufacturing System?

Key factors include the desired bread types, production capacity, available floor space, material compatibility, after-sales service provided, and whether the system aligns with your business's technological requirements.

How does an Automated Bread Line work?

An Automated Bread Line consists of different modules that perform specific tasks such as mixing, proofing, baking, and cooling in a continuous process, controlled by a computer for high precision and efficiency.

Can an Industrial Bread Manufacturing System be customized for specific business needs?

Yes, these systems can often be customized to fit the specific requirements of a bakery or food production facility, including adjustments in size, capacity, and functionality.

What are the benefits of using a Multifunctional Industrial Bread Making Machine?

Multifunctional machines offer the advantage of performing multiple bread-making steps within a single system, reducing the footprint and potentially saving on labor costs.

How do I ensure the longevity of my Industrial Bread Manufacturing System?

Regular maintenance, adherence to operational guidelines, and selecting a system from a reputable supplier who offers after-sales support are key factors in ensuring the longevity of your system.

What after-sales services are typically provided with these systems?

After-sales services can include video technical support, online support, and field maintenance and repair service. It's important to clarify with the supplier which services they offer before making a purchase.

Are there any industry-specific considerations when choosing an Industrial Bread Manufacturing System?

Yes, certain industries may have specific requirements or constraints such as space limitations, regulatory compliance, or unique production demands that need to be considered when choosing a system.

How do I handle the installation and training for an Industrial Bread Manufacturing System?

Installation and training are typically handled by experienced technicians provided by the supplier. Some suppliers may offer comprehensive support including onsite setup and training to ensure a smooth transition to using the system.

What materials are commonly used in the construction of these systems?

Common materials include stainless steel, food-grade stainless steel, aluminum, and sometimes plastic components. The choice of material often depends on the system's required durability and hygiene standards.

Can I find a supplier who can handle my order internationally?

Many suppliers on platforms like Alibaba.com offer options for international shipping. Always verify the supplier's capabilities for your region.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4