Box-making machines are tools that come in handy in the packaging industry. They simplify the production of packaging boxes for a wide range of products that cut across edible, non-edible, durable, and non-durable products. They can be used to make assorted box types, including corrugated boxes and folding cartons, among others, in different sizes.

Why are box-making machines worth the purchase?

Carton box-making machines are essential to driving logistics on a B2B scale and can significantly impact the warehousing aspect of a business. For one thing, they make packaging boxes with precision and time efficiency as well as conventionally avail production records for future reference. They come with specifications that allow users to configure their operations to suit their expected outputs in terms of size and dimensions. One way they cut costs down is by availing packaging boxes on an as-needed basis as opposed to warehousing ready-made boxes which may up recurrent costs. While it is usually best to double-check, these machines are usually designed to work within the scope of set standards and regulations on the packaging process of different product categories. To make the most of your double-check, you may want to check if the laws that your preferred box-making machine was made to align with match those in your business environment.

What are the types of box-making machines?

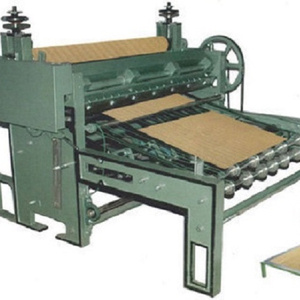

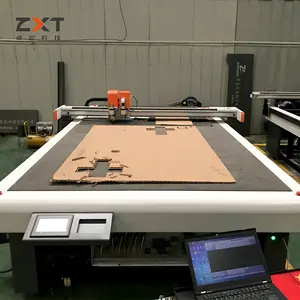

There are assorted types of soft and rigid box-making machines to choose from that differ from each other based on their purposes and functions. Reel-to-sheet cutting machines are corrugated box-making machines designed to cut each layer of ply into the projected dimensions safely and precisely to avoid waste. Sheet pasting machines are cardboard box-making machines used to paste sheets of different plies and densities together so that they form a solid single sheet. Sheet printing machines facilitate branding by printing the graphics and brand name of the product to be contained by the packaging box under process. Punching machines are designed to crease, emboss, and punch corrugated sheets to give them box-like features. While these are some of the basic and conventional, other box-making machines include box-stitching machines, rotary slotters, single facer box making machines, 2-ply corrugated paperboard box-making machines, and more that serve specific purposes, as ply sheets differ in density and sizes. These also come as manual box-making machines, semi-auto carton box-making machines, or automatic box-making machines.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4